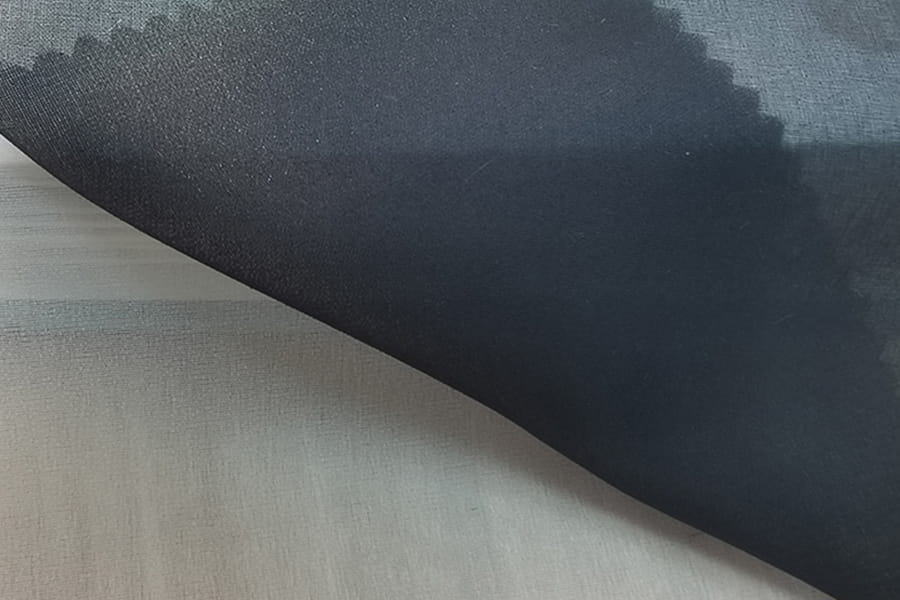

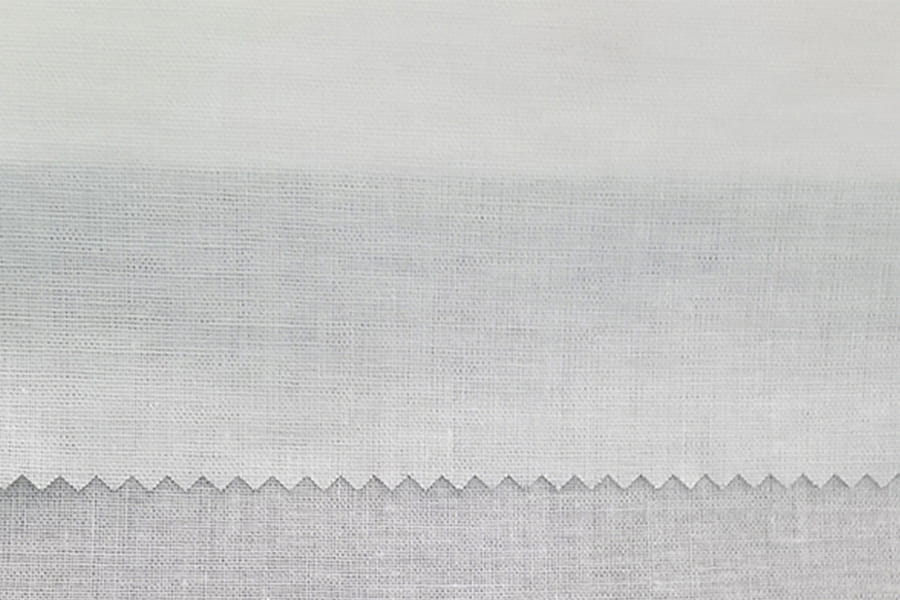

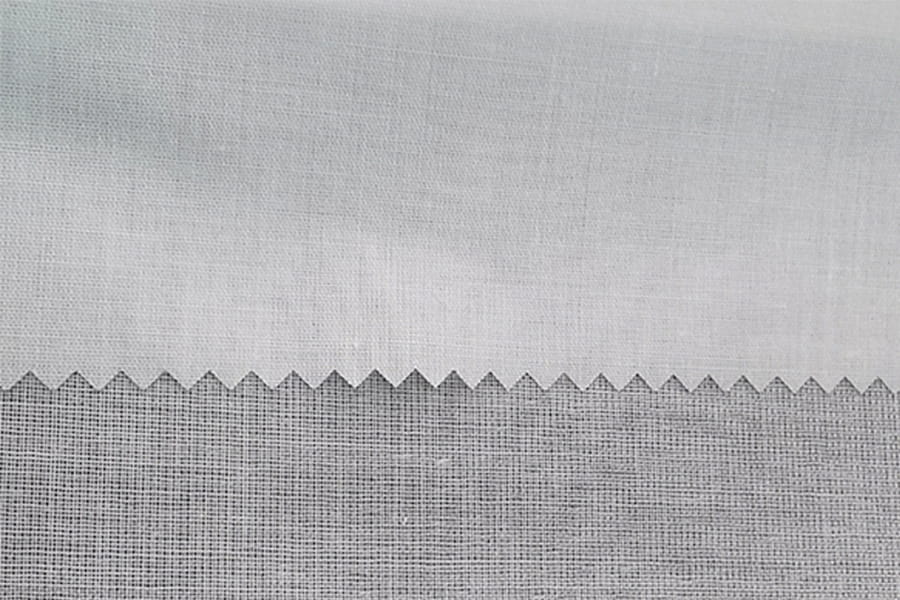

In the process of garment making, Polyester Fusible Interlining is a kind of auxiliary material commonly used to enhance the stiffness and stability of fabrics. In order to ensure the overall effect and durability of the garment, it is essential to bond the hot melt interlining correctly. Before application, it is necessary to fully understand the compatibility between the selected fabric and the hot melt interlining. Polyester hot melt interlining is suitable for medium to heavy fabrics, such as cotton, polyester-cotton blends, wool, etc., but for light or highly elastic fabrics, the model should be selected carefully. Before large-scale operation, it is best to conduct a preliminary test on a sample cloth to observe whether the hot melt interlining will cause discoloration, blistering or poor bonding of the fabric.

Next is the material preparation stage. The hot melt interlining needs to be cut into a shape consistent with the fabric, usually slightly smaller than the edge of the fabric by 1-2 mm to avoid high-temperature melt overflow and contamination of the iron or other equipment. The fabric itself should be kept clean, dry and wrinkle-free. In particular, it should be noted that wet fabrics will cause poor bonding or bubbles, affecting the final effect.

The bonding of hot melt interlining mainly depends on three key factors: temperature, pressure and time. The recommended fusing temperature range for most polyester hot melt interlinings is between 130°C and 150°C, but the specific parameters need to be referred to the product instructions. When using an iron or a press, it is necessary to apply appropriate and uniform pressure to ensure that the hot melt adhesive layer can fully penetrate into the fabric fibers. The bonding time is generally controlled between 10 and 15 seconds, which should not be too short or too long, otherwise it may cause carbonization of the adhesive layer or deformation of the fabric surface.

In the actual ironing operation, the hot melt interlining should be placed with the adhesive side facing down on the reverse side of the fabric, and then a clean cotton cloth should be used as an insulation layer to cover the surface of the fabric to prevent the iron from directly contacting the hot melt adhesive. After the iron is put down, it should be kept stationary to apply pressure instead of sliding back and forth. Sliding the iron can easily cause the hot melt interlining to be misaligned or unevenly heated locally, resulting in bubbles or wrinkles. After ironing, the fabric should be laid flat to cool for a few minutes to allow the hot melt adhesive to solidify naturally. Do not rub or bend it at this time to prevent the adhesive layer from falling off or warping before it is fixed.

Many people encounter some common problems when using hot melt interlining, such as weak adhesion, bubbling, and hardening of the fabric, which are usually caused by inaccurate operating temperature, uneven ironing, or neglect of the cooling process. Excessive temperature and pressure may also cause the melt to penetrate into the surface of the fabric, forming bright spots that are difficult to remove.

For large-scale clothing production, it is recommended to use a professional pressing machine for operation. Whether it is a flat-plate or continuous hot pressing equipment, it can achieve precise control of temperature, pressure and time, so as to ensure that the bonding effect of each hot melt interlining and the fabric is consistent and stable, improving production efficiency and finished product quality.

English

English 中文简体

中文简体 русский

русский Español

Español