Introduction: Why Functional Lining Fabrics

In modern clothing design, the functionality of fabrics is gradually becoming the core of product competitiveness. Traditional linings only play the role of covering seams and improving wearing comfort, while today's **functional linings (Functional Lining Fabrics)** have not only been comprehensively upgraded in terms of comfort, but also have multiple functions such as waterproof, anti-static, breathable, antibacterial, and warm. Whether it is outdoor sportswear, professional workwear, skiing equipment or high-end urban casual wear, these functional fabrics are not only improving user experience, but also greatly expanding the use scenarios and performance boundaries of clothing.

What Makes a Lining Fabric "Functional"?

"Functionality" is not a single indicator, but a collection of multiple performances. A functional lining usually has the following characteristics:

Waterproof and windproof: It can block the penetration of rain or cold wind to ensure the body is dry and warm.

Breathable and sweat-wicking: Ensure that sweat can be discharged in time to reduce the feeling of dampness and stuffiness.

Anti-static: Avoid static electricity in a dry environment to improve safety and comfort.

Wear and tear resistance: Increase service life, suitable for high-intensity sports or outdoor environments.

Lightweight and soft: No additional burden, keep the clothing light.

Environmental protection/sustainability: Use recyclable materials or environmentally friendly processes to meet the trend of green consumption.

Functional linings are the organic combination of these characteristics, which has promoted the dual-track evolution of clothing from "beautiful" to "technical + beautiful".

Waterproof Lining Fabrics: Top Types & Technologies

Common waterproof lining types:

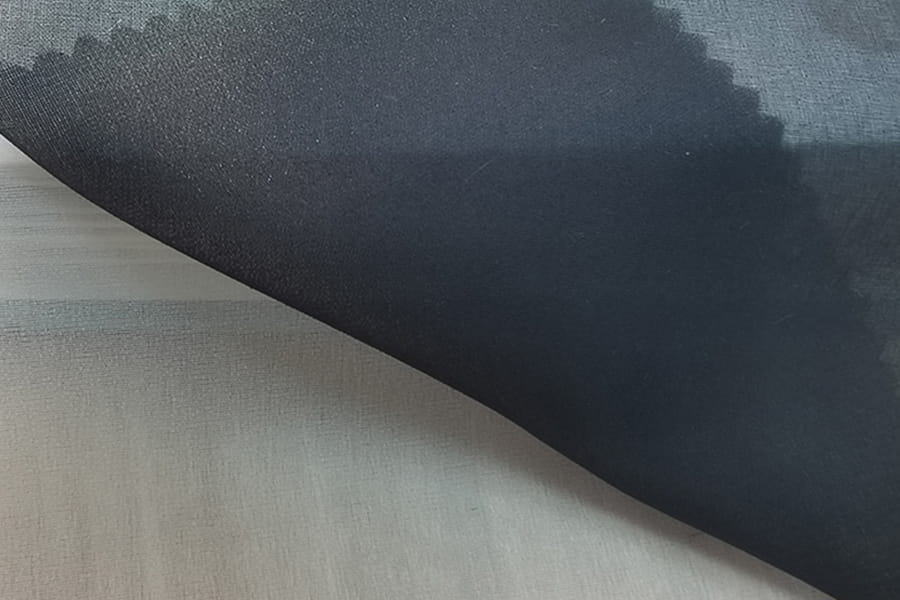

PU coated nylon or polyester

Polyurethane coating can achieve basic waterproof effect, low cost, suitable for daily raincoats or commuter wear.

PTFE membrane (such as GORE-TEX) composite materials

Provide high-level waterproof and breathable properties, widely used in high-performance equipment such as ski suits and mountaineering suits.

TPU membrane composite fabrics

Thermoplastic polyurethane membrane, environmentally friendly and with good elasticity and waterproof performance, suitable for soft shell products.

Application scenarios: ski suits, assault suits, motorcycle jackets, raincoats, tent linings, etc.

Breathable Lining Fabrics: Key Features & Best Options

Breathability is the key to measuring wearing comfort. Even highly waterproof clothing can easily cause stuffiness and discomfort if it is not breathable.

Recommended fabric types:

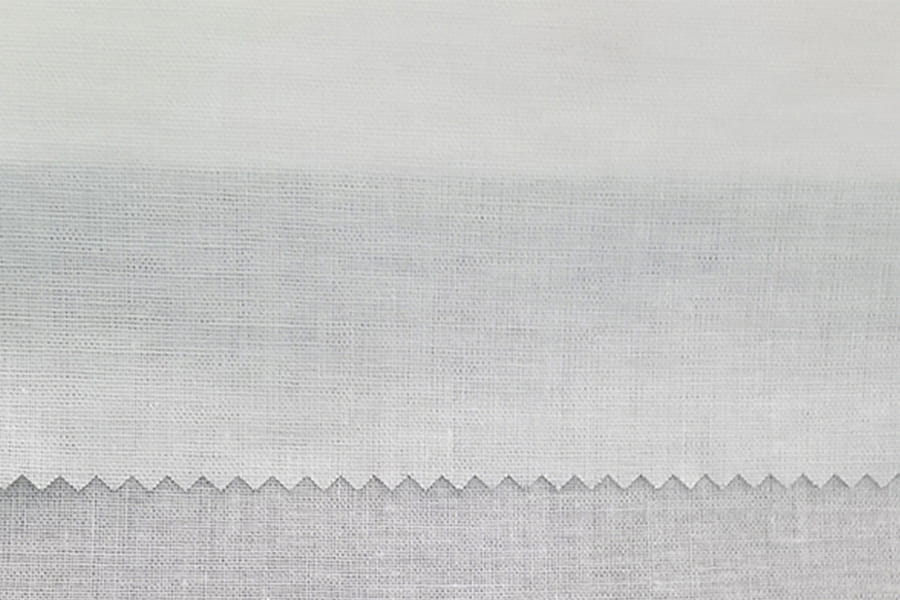

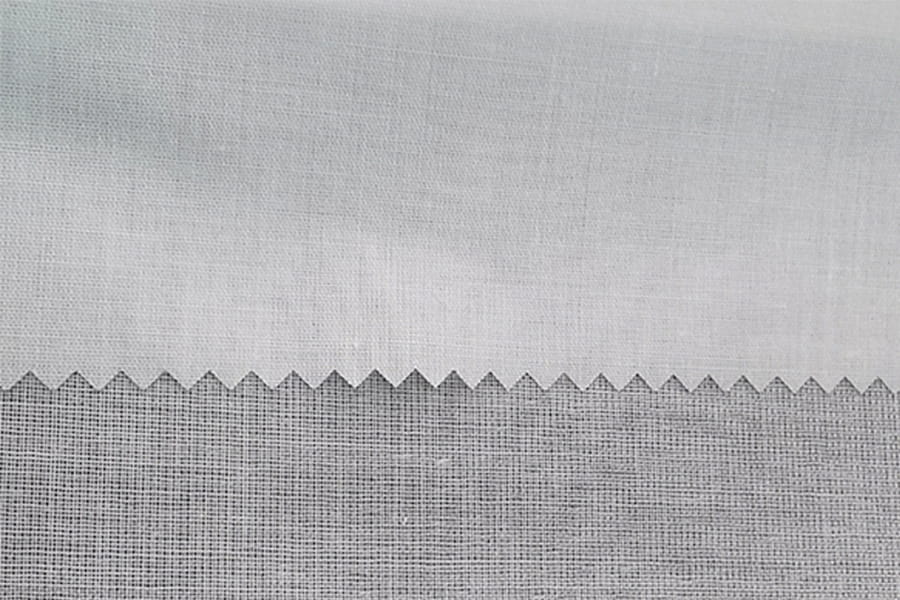

Microfiber Polyester

High density but excellent moisture permeability, suitable for sportswear and lightweight jackets.

Functional fibers such as Coolmax®/Sorona®

Outstanding moisture absorption and perspiration performance, widely used in sportswear linings.

3D Spacer Fabric

The middle layer has a three-dimensional support structure to achieve air circulation and cushioning effects.

Cotton + functional fiber blend

Comfortable feel, improved skin-friendliness, while retaining functionality.

Performance indicators:

Moisture permeability (MVTR)

Water vapor transmission rate (g/m²/24h)

Typical applications: running jackets, fitness clothes, military training clothes, and light mountaineering clothes.

Anti-Static Linings: Benefits & Common Applications

Static problems not only affect wearing comfort, but may also affect electronic products or cause safety hazards in certain industries (such as petroleum, aviation).

Common anti-static fabrics:

Conductive fiber blended polyester (containing carbon fiber or metal fiber)

Sustainably releases accumulated charges, suitable for electronic factory work clothes and laboratory coats.

Anti-static finishing coated fabrics

Anti-static treatment on the surface of ordinary fabrics, short-term effective, suitable for cost-sensitive products.

Natural fiber and carbon fiber blends

Combining comfort and functionality, used for winter anti-static clothing.

Applicable scenarios:

Medical equipment operating clothes

Industrial work clothes

Winter clothing lining (to prevent hair tangling and clothing "sticking")

English

English 中文简体

中文简体 русский

русский Español

Español