Interlining fabrics, also known as interfacing, are essential materials in the world of garment construction and home textiles. These fabrics provide structure, support, and shape retention, which are crucial for the durability, appearance, and functionality of the final product. Interlinings can be divided into various types based on their composition, application methods, and uses. Each type serves a unique purpose and can significantly impact the overall outcome of a project.

1. Fusible Interlining

Fusible interlining is one of the most commonly used types of interlining fabric, particularly in the apparel industry. The defining characteristic of fusible interlining is the presence of an adhesive coating on one side, which is activated by heat. This adhesive bonds the interlining to the fabric, eliminating the need for sewing.

Application

Fusible interlining is ideal for lightweight to medium-weight fabrics. It is widely used for adding structure to collars, cuffs, waistbands, and the inner lining of jackets and coats. Additionally, it is used in pleated garments, such as skirts and dresses, to enhance their stiffness and shape retention.

Materials

Fusible interlining is often made from synthetic fibers like polyester, cotton, or blends. The adhesive on the back of the fabric can either be a resin or a thermoplastic material that bonds when heat is applied.

Pros

- Quick and Easy Application: Fusible interlining can be easily applied using an iron, making it a time-saving option for many projects.

- Smooth Finish: The adhesive creates a clean, smooth bond without the need for visible stitching.

- Versatility: Fusible interlining works well with a wide range of fabrics, including cotton, polyester, and lightweight wool.

Cons

- Limited to Certain Fabrics: Fusible interlining may not work effectively with fabrics that are highly textured or delicate.

- Possible Adhesive Residue: If not applied correctly, the adhesive may leave a residue on the fabric, affecting its appearance and texture.

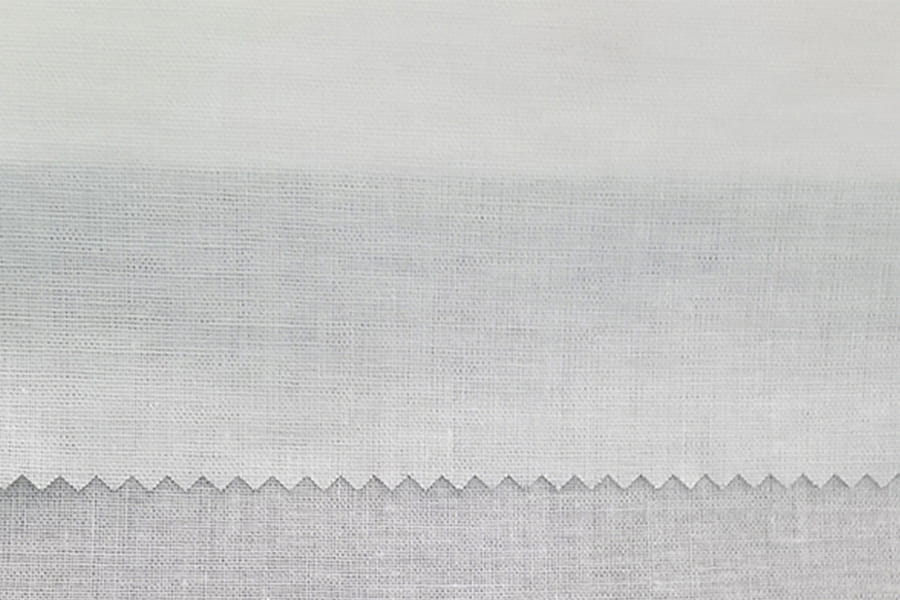

2. Non-Fusible Interlining

Non-fusible interlining is the alternative to fusible interlining and does not have any adhesive backing. Instead, it must be sewn or stitched into the fabric. This type of interlining is often used for heavier or more structured garments.

Application

Non-fusible interlining is commonly used for outerwear, suits, jackets, and coats. It is also ideal for upholstery and other home textiles where durability and structure are important. It provides a stiffer finish and is more suitable for fabrics that need extra reinforcement.

Materials

Non-fusible interlining is typically made from natural fibers like cotton, wool, or linen. Some variations may use synthetic fibers such as polyester, depending on the desired characteristics of the fabric.

Pros

- Durability: Non-fusible interlining provides added strength and longevity to the fabric, making it ideal for high-stress areas like jacket collars and cuffs.

- Versatility: It can be used with a variety of fabrics, including delicate materials like silk or textured wool.

- No Risk of Residue: As it does not have adhesive backing, there is no risk of residue or glue marks.

Cons

- More Time-Consuming: The application process is slower because the interlining must be sewn in, requiring more labor and expertise.

- Potential for Visible Stitching: Sewing in non-fusible interlining can result in visible stitching, which may not be desirable for some garments.

3. Sew-in Interlining

Sew-in interlining is another variation of non-fusible interlining. It is typically used for garments that require added structure and durability, especially those made from heavy fabrics.

Application

This type of interlining is commonly used for tailored garments, such as suits, blazers, and formal coats. It is also used for upholstery projects that require significant strength and support.

Materials

Sew-in interlining can be made from cotton, wool, or synthetic fibers. It is available in different thicknesses and weights, depending on the level of structure required.

Pros

- Long-Lasting Structure: Sew-in interlining offers excellent durability and is ideal for garments that undergo a lot of wear and tear.

- No Risk of Adhesive Damage: Since it doesn’t use adhesive, there is no risk of damage from excessive heat or adhesive residue.

Cons

- Labor-Intensive: It requires more time to apply, as it must be sewn into place.

- Visible Stitching: The stitching may be visible on the final garment, which could be undesirable for some projects.

4. Knit Interlining

Knit interlining is a type of interlining that incorporates stretchable fibers, providing both structure and flexibility. This type is particularly useful for fabrics that require some elasticity while still maintaining their shape.

Application

Knit interlining is commonly used in garments such as sportswear, activewear, and casual wear. It can also be used in garments made from stretchy fabrics like jersey or spandex to prevent distortion.

Materials

Knit interlining is made from materials like polyester, elastane, or spandex. These fibers allow the interlining to stretch and move with the fabric.

Pros

- Flexibility: The stretchability of knit interlining allows it to move with the fabric, making it ideal for activewear and stretch fabrics.

- Comfort: It provides support without sacrificing comfort or range of motion.

Cons

- Difficult to Handle: The stretchy nature of knit interlining can make it more difficult to handle during the application process.

- Not Suitable for All Garments: It may not provide enough structure for heavier fabrics or formal garments.

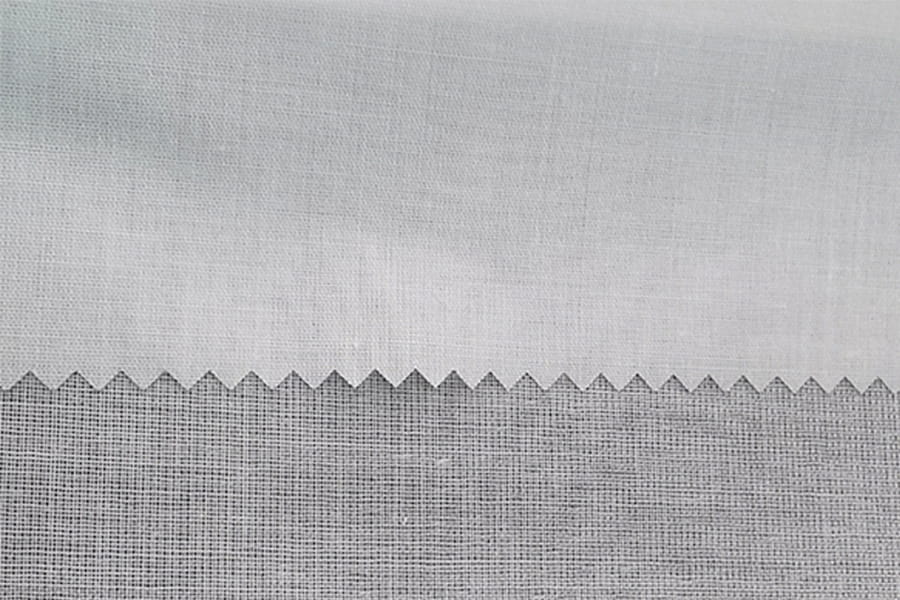

5. Woven Interlining

Woven interlining is made from tightly woven fibers, offering stability and support. It is ideal for providing structure to garments without adding excessive bulk.

Application

Woven interlining is widely used in structured garments such as shirts, blazers, suits, and formal dresses. It is also used in home textiles like curtains and upholstery to maintain shape and prevent sagging.

Materials

Woven interlining is usually made from cotton, polyester, or blends of synthetic fibers. It has a firm texture due to the tight weave of the fibers.

Pros

- Crisp Finish: Woven interlining provides a clean, crisp finish to garments and helps maintain their shape over time.

- Stability: It offers excellent structural support and stability.

Cons

- Not Suitable for Stretch Fabrics: Woven interlining may not work well with fabrics that need to stretch or move.

- Can Be Stiff: It can make the fabric feel stiffer, which may not be desirable for all garments.

6. Needle-Punched Interlining

Needle-punched interlining is made by mechanically bonding fibers together using barbed needles. This interlining is often used in industrial and heavy-duty applications where strength and durability are essential.

Application

Needle-punched interlining is typically used in upholstery, industrial textiles, and heavy outerwear. It is ideal for projects that require significant reinforcement and durability.

Materials

Needle-punched interlining is often made from polyester or nonwoven materials that are mechanically bonded.

Pros

- Durable: Offers excellent durability and strength, making it suitable for heavy-duty applications.

- Cost-Effective: It is generally less expensive than other types of interlining.

Cons

- Heavy: It can add weight to the fabric, making it unsuitable for lightweight garments.

- Less Flexible: The stiffness of needle-punched interlining may not be ideal for garments requiring flexibility.

7. Fleece Interlining

Fleece interlining is a soft, lightweight interlining that provides thermal insulation while maintaining a soft texture. It is perfect for garments that need to be both warm and lightweight.

Application

Fleece interlining is often used in outerwear, such as jackets, coats, and cold-weather garments. It can also be used in blankets and home textiles.

Materials

Fleece interlining is typically made from polyester or similar synthetic fibers that retain heat and provide insulation.

Pros

- Warmth: Provides thermal insulation without adding too much bulk.

- Soft Texture: Offers a soft feel that is comfortable against the skin.

Cons

- Can Add Bulk: It may add unnecessary bulk to thin fabrics.

- Less Breathable: Fleece may not be as breathable as other interlining types, which can cause discomfort in warmer weather.

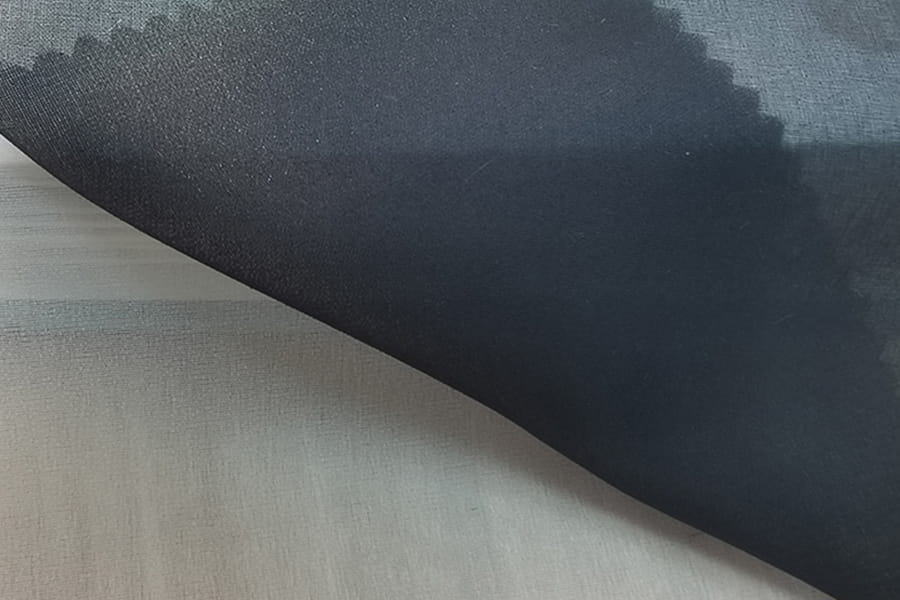

8. Laminated Interlining

Laminated interlining is a special type of interlining that has been treated with a protective layer, such as PVC or polyurethane, to provide additional waterproofing and durability.

Application

Laminated interlining is commonly used in garments and textiles that need to withstand water or harsh weather conditions, such as raincoats, outdoor jackets, and tents.

Materials

Typically made from polyester or cotton that is laminated with a waterproof coating.

Pros

- Waterproof: Provides protection against water, making it ideal for outdoor and rainy-weather garments.

- Durable: Offers increased durability and resistance to environmental elements.

Cons

- Less Breathable

The laminated coating can reduce breathability, which may cause discomfort during long periods of wear.

- Can Be Stiff: The laminated layer may add stiffness to the fabric.

9. Silk Interlining

Silk interlining is a luxurious type of interlining made from silk fibers. It offers a soft and smooth finish, perfect for high-end fashion and delicate fabrics.

Application

Silk interlining is often used in formal wear, such as evening dresses, luxury suits, and other high-fashion garments. It is also used in upholstery for premium furniture.

Materials

Made from pure silk or silk blends, providing a soft, smooth texture.

Pros

- Luxurious Finish: Silk interlining adds a touch of luxury to garments.

- Soft and Lightweight: It is ideal for delicate fabrics and provides a gentle finish without adding weight.

Cons

- Expensive: Silk is a high-end material, making silk interlining quite costly.

- Requires Special Care: Silk interlining requires careful handling and maintenance to preserve its quality.

10. Fusible Fleece Interlining

Fusible fleece interlining combines the soft insulation properties of fleece with the convenience of fusible interlining. It has a heat-activated adhesive that bonds the fleece to the fabric.

Application

Fusible fleece is perfect for quilting, bags, outerwear, and any project requiring added warmth without excessive weight.

Materials

Made from polyester fleece with a fusible adhesive coating.

Pros

- Warmth Without Bulk: Provides warmth and insulation without making the fabric too heavy.

- Easy to Apply: The fusible adhesive makes it easy to attach the interlining to the fabric.

Cons

- Can Be Bulky: May not be suitable for very lightweight fabrics.

- Not Ideal for All Fabric Types: The adhesive may not bond well with all types of fabric, particularly delicate ones.

English

English 中文简体

中文简体 русский

русский Español

Español