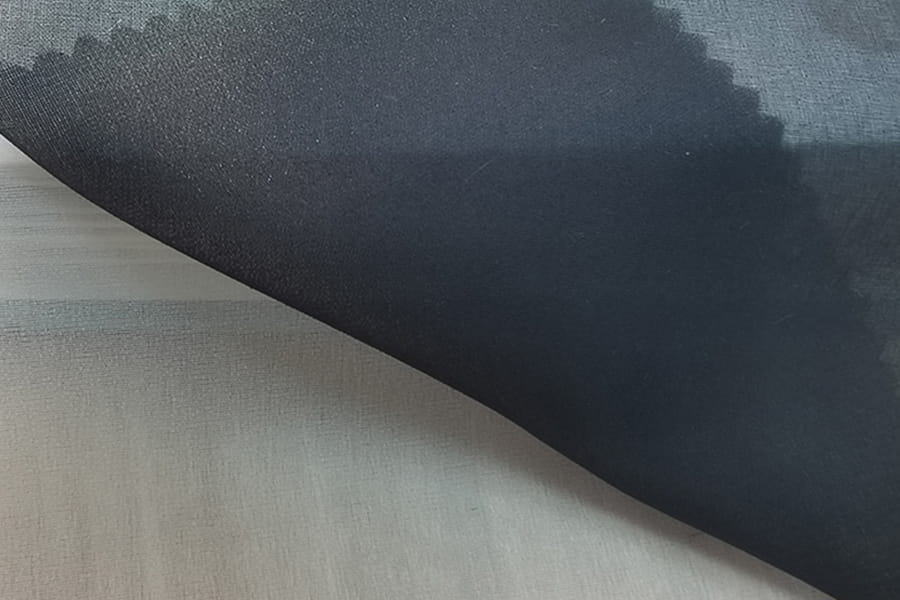

Woven Fusible Interlinings plays an indispensable role in modern clothing design. It not only improves the appearance of clothing, but also directly affects the comfort, durability and wearing experience of clothing. As an important auxiliary material, Woven Fusible Interlinings can achieve higher standards in the design, manufacturing and wearing process of clothing by enhancing the structure and support of the fabric. As consumers' requirements for clothing quality increase, designers are increasingly relying on this material to create clothing that is both fashionable and comfortable and practical.

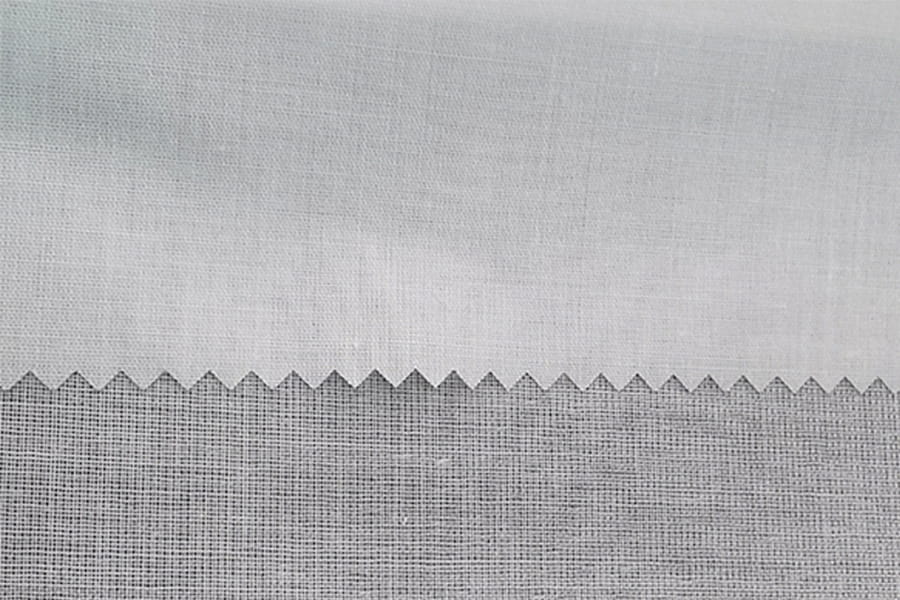

One of the main functions of Woven Fusible Interlinings is to enhance the structure and stability of the fabric. For some parts of clothing that need to maintain their shape, such as collars, cuffs, and lapels, Woven Fusible Interlinings plays a vital role. It can provide these parts with the necessary support to avoid deformation, collapse and other problems during wearing. Especially in suits, coats and other clothing that require three-dimensionality and exquisite shapes, Woven Fusible Interlinings can ensure the stiffness of the clothing, making the overall design more refined and sophisticated. This interlining usually has a certain elasticity, so even if the fabric remains stiff, the comfort and softness of the clothing will not be affected.

Woven Fusible Interlinings also play an important role in improving the appearance of clothing. It helps the fabric spread more evenly, making the folds of the clothing neater and smoother. For high-end clothing designs that require precise tailoring, Woven Fusible Interlinings can help the clothing maintain its ideal shape and prevent unnecessary undulation or loss of shape. The use of this interlining allows designers to focus more on the overall design when creating, without worrying about loose or unstable fabrics. In addition, it can make the lines of clothing smoother and the overall shape more capable.

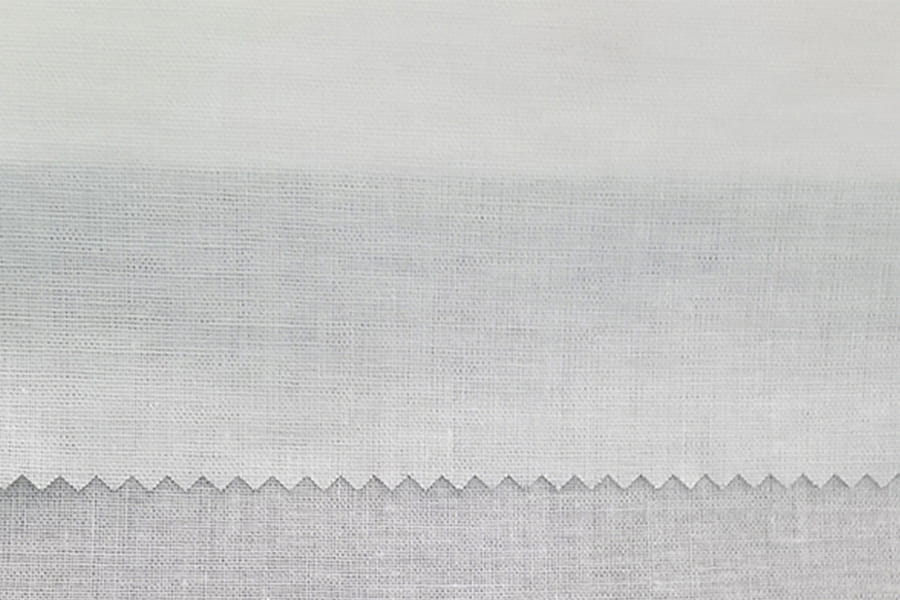

Woven Fusible Interlinings also have the characteristics of enhancing the durability of fabrics, especially in some areas that are prone to wear and tear. Clothing is often subjected to friction during daily wear, especially in areas such as collars and cuffs. Without proper support, these areas are easily damaged. Clothing with Woven Fusible Interlinings can effectively increase the wear and tear resistance of clothing, extending the service life of clothing. In the case of frequent washing, this interlining can maintain the stability of clothing and prevent the fabric from deforming or aging prematurely, thereby greatly improving the durability of clothing.

In addition to enhancing the stiffness and durability of clothing, Woven Fusible Interlinings can also improve the comfort of clothing. Many people may think that the use of interlinings for added support makes clothing uncomfortable. Woven Fusible Interlinings provide structural support while ensuring comfort with its softness and elasticity. Whether it is workwear, sportswear, or daily wear, designers can choose the appropriate interlining thickness and hardness according to specific needs to ensure that the clothing has both a sense of structure and sufficient freedom of movement for the wearer.

The importance of Woven Fusible Interlinings in clothing design is also reflected in the improvement of efficiency in the production process. Traditional interlinings need to be combined with fabrics by hand sewing, which is not only time-consuming and labor-intensive, but may also affect the quality of the final product. Woven Fusible Interlinings use an iron-on bonding method, which is a quick and efficient process that simplifies the clothing production process. Designers can complete precise bonding in a shorter time, reducing production time and costs. At the same time, this fast and precise process also ensures the overall quality of the clothing, especially in large-scale production, to ensure the consistency and refinement of each garment.

English

English 中文简体

中文简体 русский

русский Español

Español