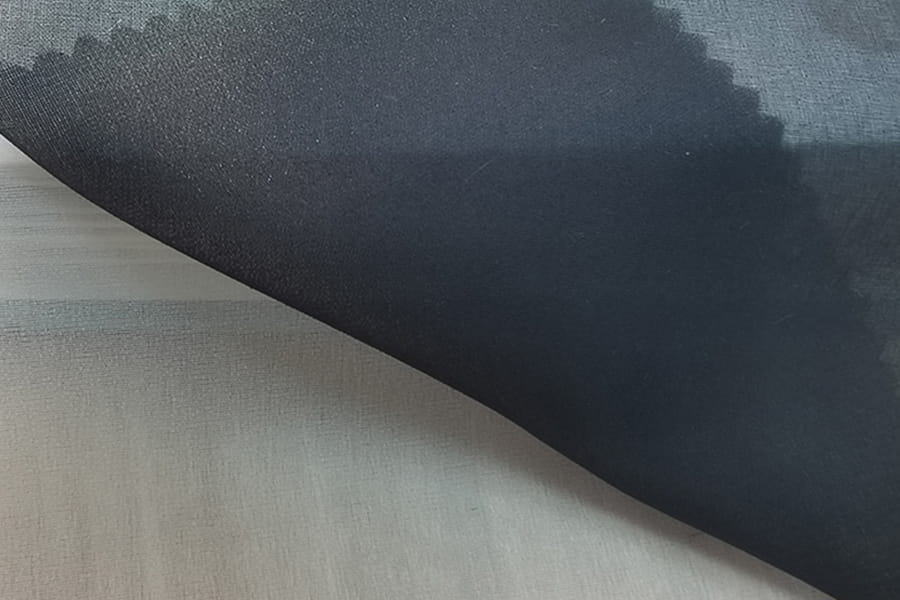

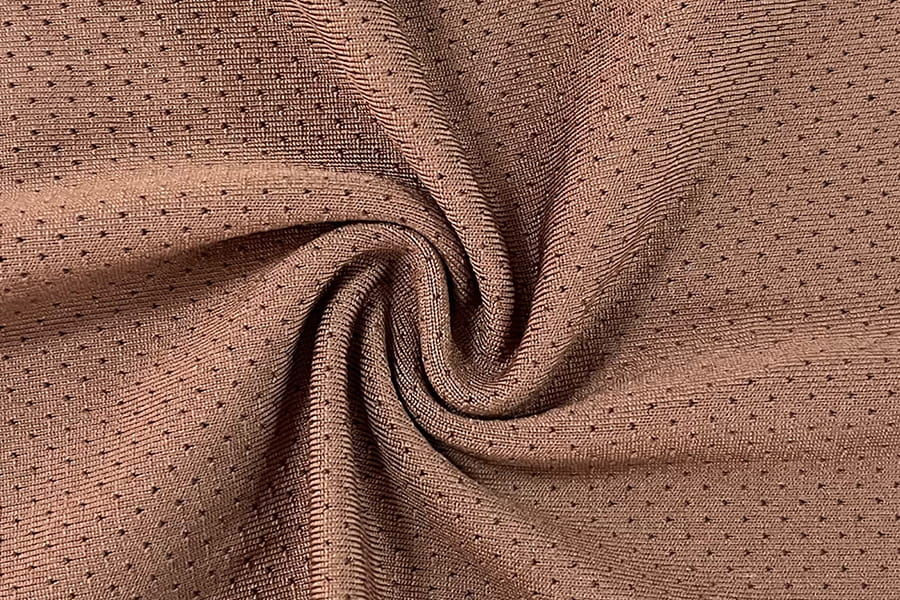

Polyester knitted fabric, commonly used in clothing, activewear, and home textiles, has become a subject of increased interest due to its environmental impact. As the demand for sustainable fashion and textiles grows, the question arises: Can polyester knitted fabric be recycled and repurposed for new products? The answer is yes, but the process involves various methods and challenges.

1. Mechanical Recycling

Mechanical recycling is the most common and established method used to recycle polyester knitted fabric. It involves breaking down the fabric into smaller pieces, cleaning them, and then re-spinning them into new yarns. These yarns are then used to produce new textiles, often for lower-value products like insulation or industrial fabrics.

The Process:

- Shredding: The polyester fabric is shredded into small pieces.

- Cleaning: The shredded fabric is cleaned to remove any contaminants, such as dirt, dyes, or chemicals.

- Spinning: The clean fibers are spun into new yarns, which are then woven or knitted into fresh fabric.

One of the key benefits of mechanical recycling is that it is a relatively low-cost process. However, the quality of the recycled polyester can degrade over time. This means that fabrics made from recycled polyester may not be suitable for high-end fashion or premium products. Additionally, the process is limited by the type of fabric being recycled. For example, polyester that is heavily blended with other fibers may not be suitable for mechanical recycling.

| Stage | Description |

|---|---|

| Shredding | Fabric is cut into smaller pieces to be processed. |

| Cleaning | Contaminants such as dyes and chemicals are removed. |

| Spinning | Recycled fibers are spun into new yarns, which are then woven or knitted into new fabric. |

| Reuse | The resulting fabric can be used for lower-value products like insulation, blankets, or upholstery. |

Benefits:

- Cost-effective: Mechanical recycling is cheaper than chemical processes.

- Low environmental impact: It helps reduce the amount of waste sent to landfills.

Drawbacks:

- Degradation in quality: The fabric may lose some of its original strength and texture.

- Limited reuse in high-end fashion: Recycled polyester from this process is typically used for less demanding applications.

2. Chemical Recycling

Chemical recycling is a more advanced process that can potentially offer higher-quality recycled polyester compared to mechanical methods. This process breaks the polyester down into its basic chemical components, known as monomers, which can then be used to create new polyester fibers of the same quality as virgin polyester.

The Process:

- Depolymerization: The polyester fabric is broken down into its original monomers through heat or chemical treatments.

- Purification: The monomers are purified to remove any contaminants.

- Repolymerization: The purified monomers are re-polymerized to form new polyester fibers.

Chemical recycling is more complex and expensive than mechanical recycling but has a distinct advantage: it can produce high-quality polyester suitable for fashion and other premium products. This method also reduces the loss of quality after each recycling cycle.

| Stage | Description |

|---|---|

| Depolymerization | Polyester is broken down into its original monomers. |

| Purification | The monomers are cleaned to remove contaminants, ensuring a high-quality result. |

| Repolymerization | The purified monomers are reformed into high-quality polyester fibers. |

Benefits:

- High-quality recycled polyester: Chemical recycling produces fibers that are as strong and durable as virgin polyester.

- Sustainability: The process reduces waste and the need for virgin raw materials.

Drawbacks:

- High cost: The technology is still in development, and the cost of the process is currently higher than mechanical recycling.

- Energy-intensive: The process requires significant energy, which can reduce its overall environmental benefits.

3. Upcycling and Repurposing

Upcycling is a creative way to reuse polyester knitted fabric without necessarily recycling it through mechanical or chemical processes. In upcycling, the fabric is repurposed into new products or even fashion items without undergoing significant changes. This method promotes creativity and adds value to waste material by giving it a second life.

The Process:

- Re-purposing Existing Fabric: Rather than breaking down the fabric, it is transformed directly into new products.

- Designing New Products: Items such as bags, accessories, or home textiles are made from pre-existing polyester fabrics.

Upcycling does not involve breaking the material down to its core components. Instead, it focuses on finding ways to reuse and reimagine existing fabrics, often through creative design or altering the fabric’s form.

Examples of Upcycled Products:

- Fashion: Bags, jackets, or even new garments.

- Home Goods: Cushions, throws, or decorative pieces.

- Industrial Uses: Polyester fabric can also be used for insulation, seat covers, or even carpet padding.

| Product Type | Example of Repurposed Items |

|---|---|

| Fashion | Bags, jackets, or upcycled garments made from used polyester fabrics. |

| Home Goods | Cushions, blankets, and other interior decor products. |

| Industrial Goods | Upholstery, insulation, and automotive seat covers made from repurposed polyester. |

Benefits:

- Reduces waste: Helps divert fabric from landfills by giving it new uses.

- Cost-effective: Since it does not require breaking down the fabric, upcycling can be a cheaper alternative.

- Creative and sustainable: Upcycling encourages innovation and provides sustainable alternatives to new products.

Drawbacks:

- Limited scalability: Upcycling relies heavily on creativity and is often limited by the type and condition of the fabric.

- Quality variation: The resulting products might not always meet the same standards as new products.

4. Challenges in Recycling Polyester Knitted Fabrics

While polyester is technically recyclable, several challenges complicate the recycling of knitted fabrics. These challenges can impact the efficiency and effectiveness of polyester recycling processes.

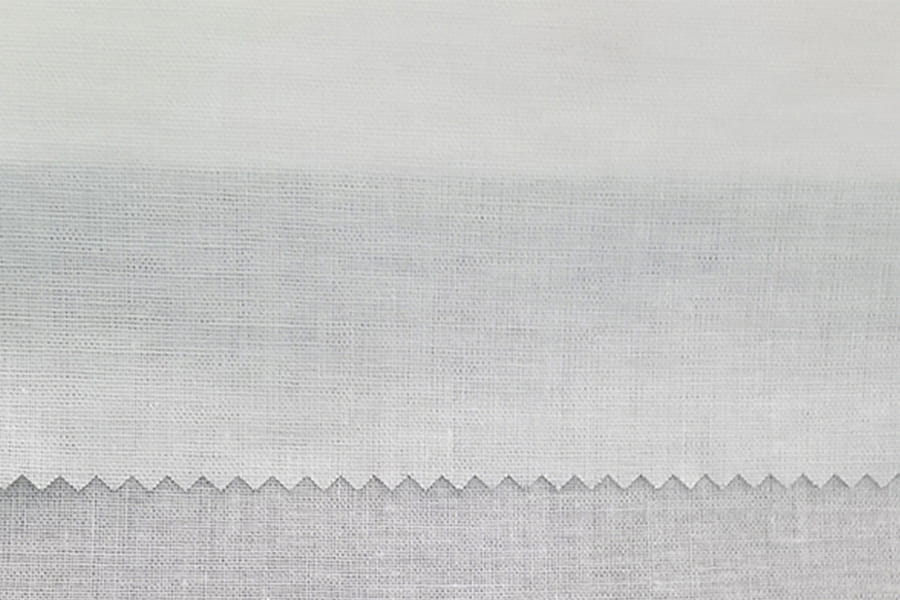

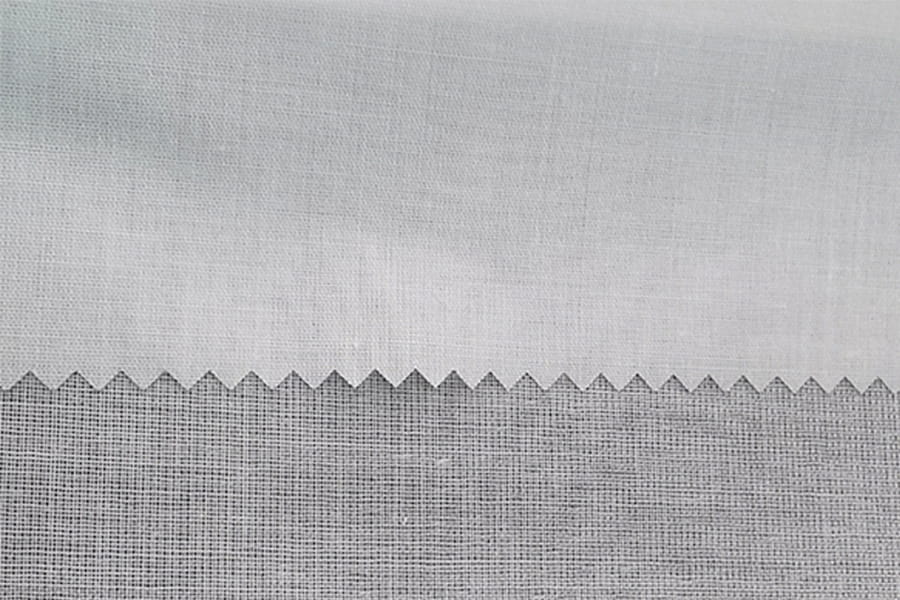

1. Blended Fabrics

Polyester is often blended with other fibers, such as cotton, elastane, or spandex. These blends make it difficult to recycle the fabric efficiently since the different fibers require separate processing methods.

2. Dyeing and Chemical Treatments

Many polyester fabrics are dyed or treated with chemicals to improve their appearance, texture, or performance. These treatments can contaminate the recycling process, making it more difficult to produce high-quality recycled fibers.

3. Collection and Sorting

For effective recycling, polyester fabrics need to be sorted by type, color, and condition. However, textile recycling systems often face challenges in efficiently collecting and sorting used fabrics, which can limit the volume of fabric that can be processed.

5. Recycled Polyester in the Market

Recycled polyester, commonly known as rPET (recycled polyethylene terephthalate), is increasingly being used in the fashion and textile industries. Many brands have started adopting rPET to reduce their carbon footprint and reliance on virgin polyester. Recycled polyester can be made from post-consumer waste like plastic bottles or from post-industrial waste, including leftover fabrics.

Applications of rPET:

- Clothing: Activewear, sportswear, and outerwear.

- Home Textiles: Bedding, rugs, and upholstery.

- Accessories: Bags, shoes, and accessories made from sustainable materials.

English

English 中文简体

中文简体 русский

русский Español

Español