Introduction

Polyester fusible interlining is an indispensable material in modern garment construction. It is designed to bond with fabrics when heat is applied, giving garments structure, stability, and a polished finish. Whether you are sewing tailored jackets, formal dresses, or casual shirts, understanding how and why polyester fusible interlining works can make a huge difference in the quality and durability of your finished clothing.

Using interlining correctly ensures that garments maintain their shape and appearance over time. Without it, fabrics can sag, wrinkle, or lose their professional look, especially in areas that undergo stress, such as collars, cuffs, waistbands, and plackets.

What Is Polyester Fusible Interlining?

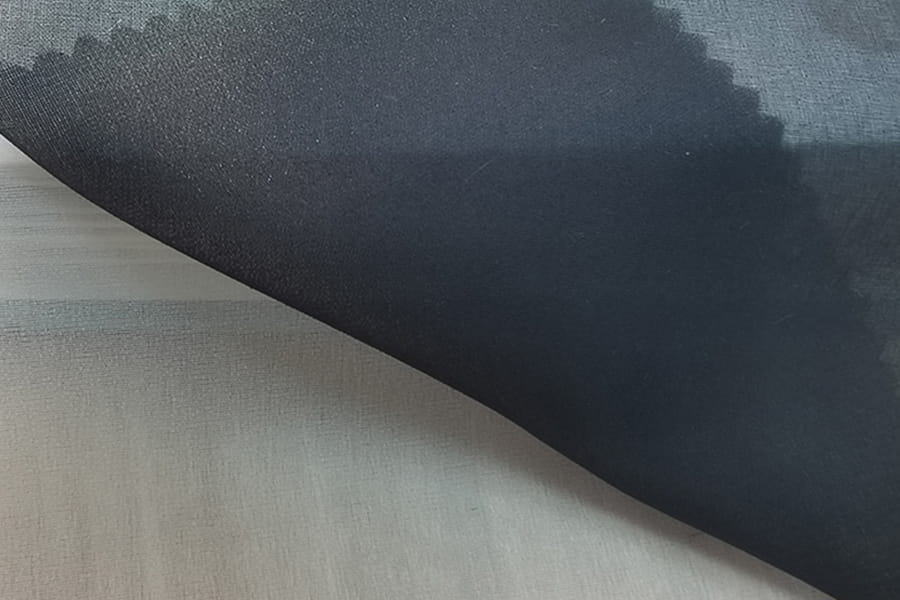

Polyester fusible interlining is a specialized fabric that has a layer of heat-activated adhesive on one or both sides. When applied to the main fabric with an iron or heat press, the adhesive melts and bonds securely to the fabric, creating reinforcement without the need for hand-stitching.

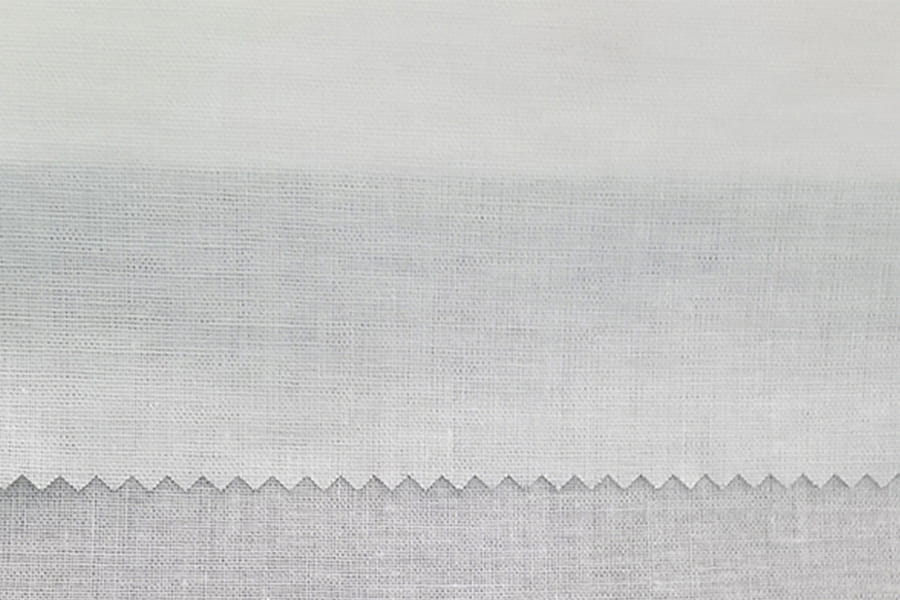

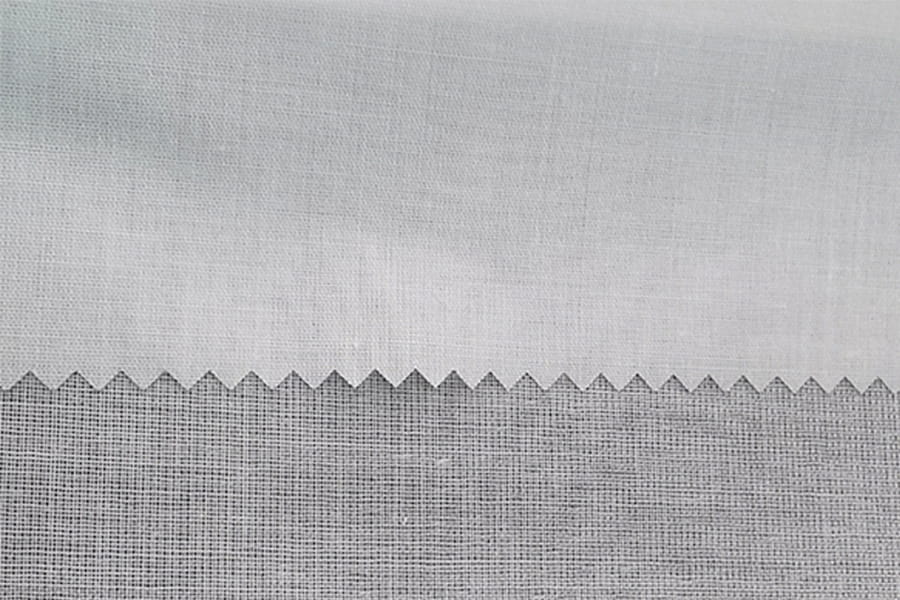

Unlike non-fusible interlinings, which require sewing to attach, fusible interlining simplifies the garment construction process and reduces sewing time. It comes in various weights and thicknesses to suit different types of fabrics and garments.

Benefits of Using Polyester Fusible Interlining

Polyester fusible interlining provides multiple advantages that make it essential in garment construction:

- Adds Stability: It helps fabrics hold their shape, preventing stretching or sagging in critical areas.

- Prevents Wrinkling: It keeps garments looking crisp, even after multiple washes or prolonged wear.

- Improves Durability: Reinforces areas prone to wear, such as collars, cuffs, and pocket openings.

- Enhances Appearance: Creates a professional, structured finish that elevates the garment’s overall quality.

- Saves Time: Fusible interlining eliminates the need for hand-stitching, speeding up the production process.

Comparison Between Fusible and Non-Fusible Interlining

| Feature | Fusible Interlining | Non-Fusible Interlining |

|---|---|---|

| Attachment Method | Iron-on adhesive | Sew-in only |

| Ease of Use | Quick and easy | Time-consuming |

| Stability & Shape Retention | High | Moderate |

| Professional Finish | Smooth and polished | Less consistent |

| Best Use | Collars, cuffs, waistbands, jackets | Soft garments, quilts, light fabrics |

This table highlights why fusible interlining is preferred in many tailoring and garment-making scenarios.

Why Is It Essential in Garment Construction?

Without proper interlining, garments may lose shape, wrinkle easily, or look unfinished. Polyester fusible interlining is essential for creating structured and professional-looking garments, particularly in formal wear, tailored jackets, and coats.

Tailors and designers rely on fusible interlining because it allows them to achieve consistent quality and durability. For example, in a blazer, fusible interlining ensures that the lapels and collar maintain their crisp lines, even after extended wear.

Tips for Using Polyester Fusible Interlining

To maximize the benefits of polyester fusible interlining, follow these best practices:

- Test on Fabric Scraps: Always try fusing on a small piece of fabric before applying it to the final garment.

- Use Correct Heat: Follow the manufacturer’s instructions for temperature and pressing time to avoid fabric damage.

- Avoid Stretching: Do not pull or stretch the fabric while fusing, as it can create puckers.

- Match Weight to Fabric: Choose an interlining weight suitable for your fabric; heavy fabrics require heavier interlining, and light fabrics require lighter interlining.

- Press Evenly: Apply even pressure when fusing to ensure full adhesion.

English

English 中文简体

中文简体 русский

русский Español

Español