1. Introduction

In garment production, interlining is a detail that cannot be ignored. Woven Fusible Interlining can significantly improve the structure, shape stability and overall texture of garments. If the wrong interlining is chosen, even if the fabric and design are excellent, it may cause the garment to deform, bubble or be uncomfortable to wear.

2. What is Woven Fusible Interlining?

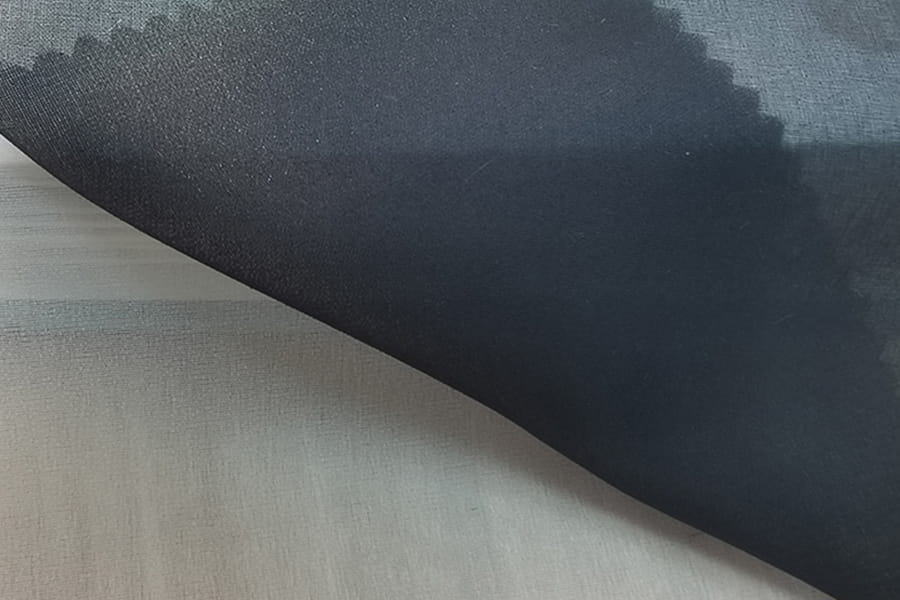

Woven Fusible Interlining is an interlining made by applying glue dots or glue powder to woven fabrics, which can be bonded to the fabric under high temperature and pressure.

The biggest difference between it and Non-Woven Interlining is that woven interlining has a warp and weft interlaced structure, which has better durability, flexibility and breathability, and is more suitable for high-end fabrics such as wool, silk, cotton and linen blends.

Common applications include:

Shirt collars and cuffs: maintain a crisp shape.

Suits and jackets: enhance three-dimensionality and shape stability.

Dresses and fashion clothing: improve overall drape.

3. Why Choosing the Right Interlining Matters

Choosing the wrong interlining will directly affect the quality of the finished garment.

Impact on fabric drape: Too stiff or too thick interlining will make the garment look stiff and unnatural.

Durability issues: Low-quality or mismatched interlining may debond and bubble after a few washes.

Reduced comfort: The wrong interlining will make the garment lose its softness or breathability.

Choosing Woven Fusible Interlining correctly can ensure that the garment looks crisp, comfortable and durable.

4. Key Factors to Consider When Choosing Woven Fusible Interlining

Fabric Type and Weight

Fabric weight and thickness are the primary considerations:

Light fabrics (such as silk, chiffon): Choose light and soft woven fusible interlining to maintain the fluidity of the fabric.

Medium fabrics (such as cotton, polyester): Medium-weight interlining is suitable for shirt collars, plackets and other parts.

Heavy fabrics (such as wool, denim): use a stiffer woven interlining to enhance the sense of structure.

Adhesive Type (Coating)

The type of adhesive affects the bonding effect and feel:

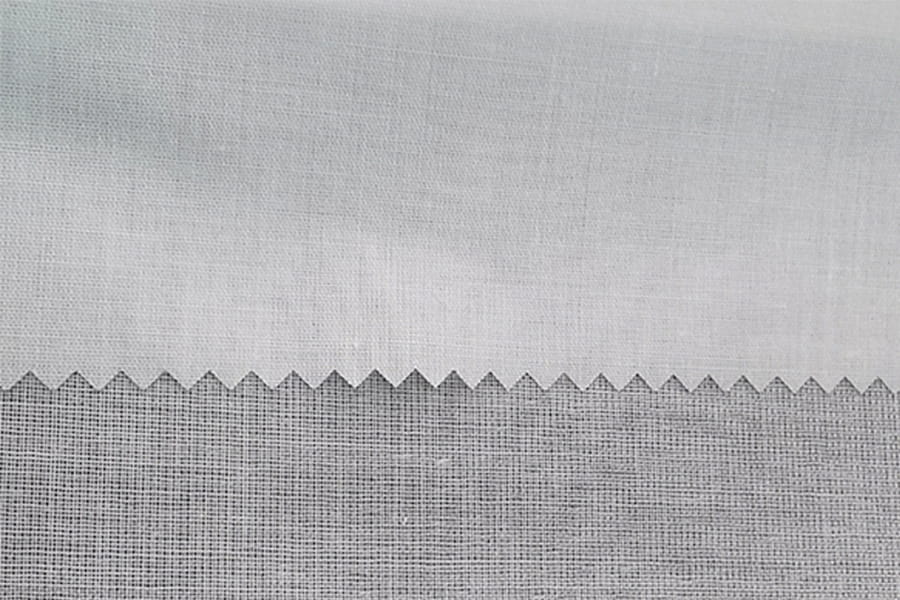

Single-dot: suitable for light and thin fabrics, better breathability.

Double-dot: suitable for medium and thick fabrics, stronger bonding.

Powder-dot: suitable for special fabrics, more uniform bonding.

When choosing, consider the heat resistance of the fabric and the bonding temperature.

Shrinkage and Wash Durability

Interlining with too high shrinkage will cause the clothes to deform after washing. Recommended selection:

Pre-shrunk woven interlining.

Products that can withstand multiple washing and dry cleaning are suitable for high-end clothing such as suits and jackets.

Hand Feel and Flexibility

The softness and elasticity of the interlining should be coordinated with the fabric:

High-end suits require stiff interlining to create a three-dimensional effect.

Women's clothing or silk fabrics need to choose soft woven interlining to maintain an elegant and flowing feel.

Color Matching

Color is also a detail:

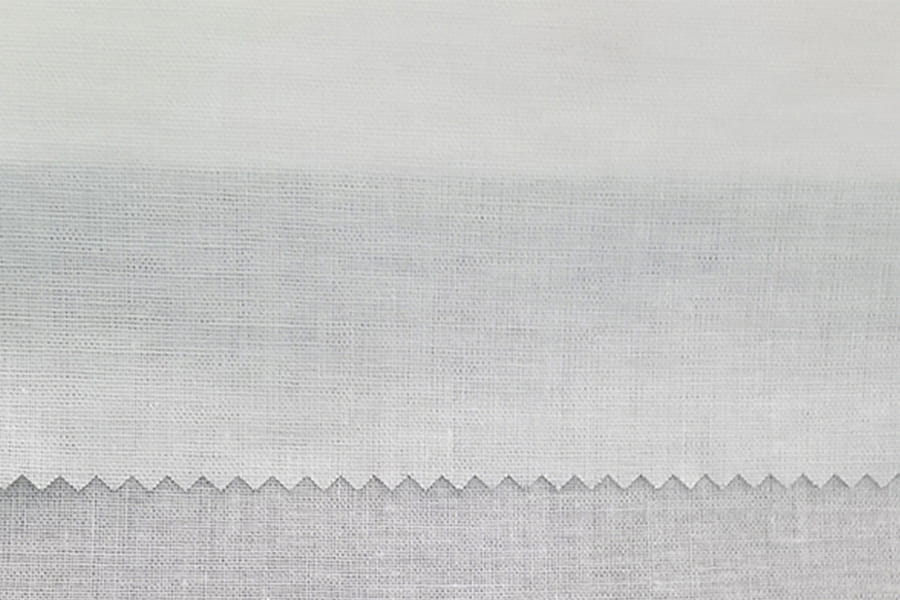

White lining: suitable for light-colored fabrics.

Black or dark lining: avoid color see-through problems.

Gray: suitable for neutral-toned fabrics.

5. Testing Before Final Use

Before formal mass production, be sure to do testing:

Ironing temperature test: determine the optimal temperature to avoid high temperature causing fabric damage or lining failure.

Pressure and time test: different fabrics require different pressure and time, and too high pressure may cause glue to seep out.

Washing test: ensure that the bond is strong and can withstand washing.

English

English 中文简体

中文简体 русский

русский Español

Español