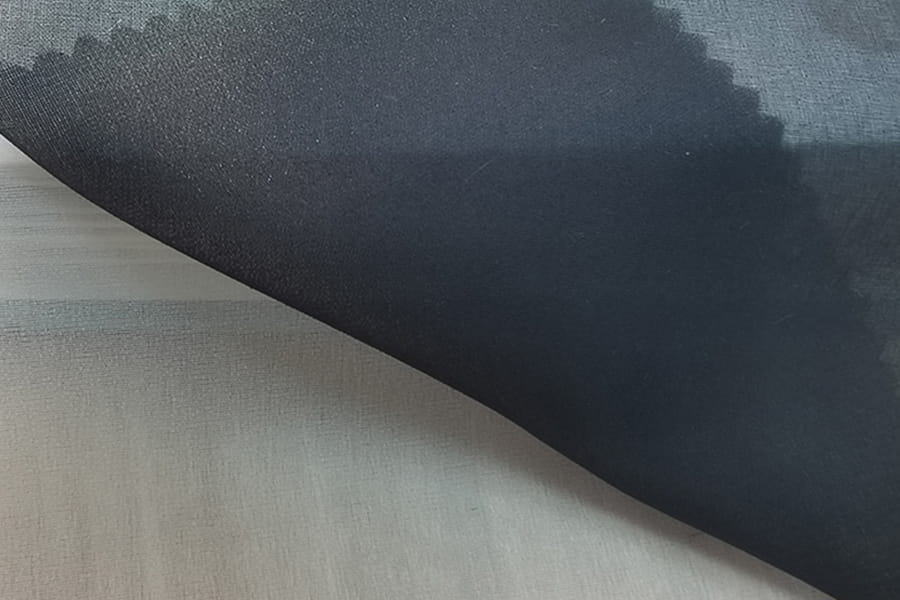

Polyester fusible interlining has become a cornerstone material for professional tailors due to its numerous benefits. Whether you’re crafting bespoke garments or looking for efficient ways to enhance mass-produced apparel, understanding the advantages of this material can elevate the quality of your creations.

1. Adds Structure and Stiffness

One of the most prominent reasons for using polyester fusible interlining in tailoring is its ability to provide structure and stiffness to a garment. Certain parts of a garment, like collars, cuffs, waistbands, and plackets, require added support to keep their shape and form throughout the day. Without this reinforcement, these areas can sag, become limp, or lose their crispness, resulting in a poorly fitted or unprofessional look.

How It Works: The adhesive coating on the fusible interlining bonds to the fabric when heat is applied, making these parts of the garment more rigid and resistant to wear. This helps maintain a sharp, structured silhouette.

Example: A suit jacket benefits greatly from fusible interlining in its collar and front panels. The added structure ensures that the jacket maintains its clean lines and doesn’t lose its crisp appearance after hours of wear.

2. Improves Durability

Polyester is known for its durability, and when used as fusible interlining, it significantly enhances the longevity of the fabric it’s bonded with. The fabric becomes more resistant to fading, shrinking, and stretching, which is particularly important for high-stress areas like collars, cuffs, and waistbands.

How It Works: The polyester material itself is tough, which means it adds strength to delicate or soft fabrics, protecting them from the wear and tear of daily use. The fusible bonding process ensures that the interlining stays in place, even after multiple washes.

Example: A wool blazer with fusible interlining in the collar will maintain its shape and crispness even after repeated dry cleaning and daily use. Over time, the garment will age well without losing its structural integrity.

3. Quick and Efficient Application

Tailors often face tight deadlines, especially when working on custom orders or mass-producing garments. Polyester fusible interlining provides a quick and efficient solution that saves time compared to traditional sew-in interlining.

How It Works: Instead of stitching the interlining into the fabric, which can be time-consuming, polyester fusible interlining adheres directly to the fabric with the application of heat and pressure. This process eliminates the need for hand-sewing or machine stitching, streamlining production.

Example: A tailor working on a batch of custom shirts can apply fusible interlining to collars and cuffs in a fraction of the time it would take to sew in a traditional interlining. This speed boosts productivity, especially in a fast-paced environment like a tailoring shop or factory.

4. No Visible Stitches or Seams

For high-end garments, appearance is everything. Polyester fusible interlining bonds seamlessly with the fabric, creating a clean, seamless finish. This is especially important in bespoke clothing where every detail counts.

How It Works: The fusible interlining is applied on the inside of the fabric and adheres through heat, leaving no visible marks or stitching on the outside. This results in a sleek, professional look without any telltale signs of the interlining.

Example: A couture evening gown made from luxurious fabric like silk or satin requires a flawless finish. The use of polyester fusible interlining ensures that there are no visible seams or bulky stitching, preserving the garment's elegant, smooth lines

5. Versatility Across Fabric Types

Polyester fusible interlining is highly versatile, making it suitable for a wide range of fabrics, from delicate materials like silk to heavy-duty fabrics like wool or denim. This adaptability allows tailors to use the same type of interlining for different garment types, ensuring consistent quality across a variety of materials.

How It Works: Polyester fusible interlining is available in various weights and thicknesses, which allows the tailor to choose the right option based on the fabric they are working with. Lighter fabrics may require a thin, lightweight fusible interlining, while heavier fabrics may need a thicker one to provide the necessary support.

Example: For a lightweight silk blouse, a lightweight fusible interlining will ensure the fabric remains soft and fluid, while a heavier fusible interlining would be perfect for a wool coat that needs extra structure and shape.

6. Reduces the Risk of Fabric Damage

Traditional sew-in interlining often requires hand-stitching or machine sewing, which can lead to fabric distortion, puckering, or fraying—especially with delicate fabrics. Polyester fusible interlining eliminates this risk, providing a non-invasive solution that bonds to the fabric without stitching.

How It Works: The fusible adhesive melts under heat and bonds with the fabric, ensuring a perfect, smooth connection without compromising the integrity of the textile. This is especially important when working with fabrics that are prone to damage from stitching.

Example: When tailoring a fine silk dress, using polyester fusible interlining allows the tailor to reinforce the garment without causing any damage to the delicate silk fibers, keeping the fabric’s texture and appearance intact.

7. Cost-Effective Solution

Polyester fusible interlining is generally more affordable than natural fiber alternatives, such as cotton or linen interlining, making it a budget-friendly choice for tailors and garment manufacturers. Its affordability doesn’t mean a sacrifice in quality—it still provides excellent durability and performance.

How It Works: The production costs for polyester interlining are relatively lower compared to natural fiber options, which makes it a great choice for both small-scale and mass-market tailoring. It offers a cost-effective option without compromising on performance.

Example: A tailoring business producing a large number of shirts can keep costs down while ensuring that each garment has the necessary structure and support by opting for polyester fusible interlining rather than pricier alternatives.

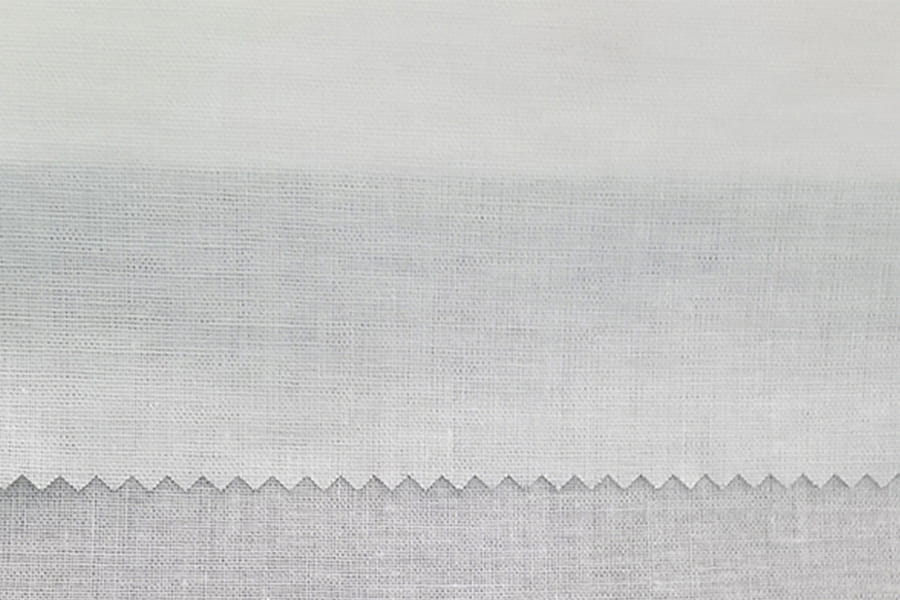

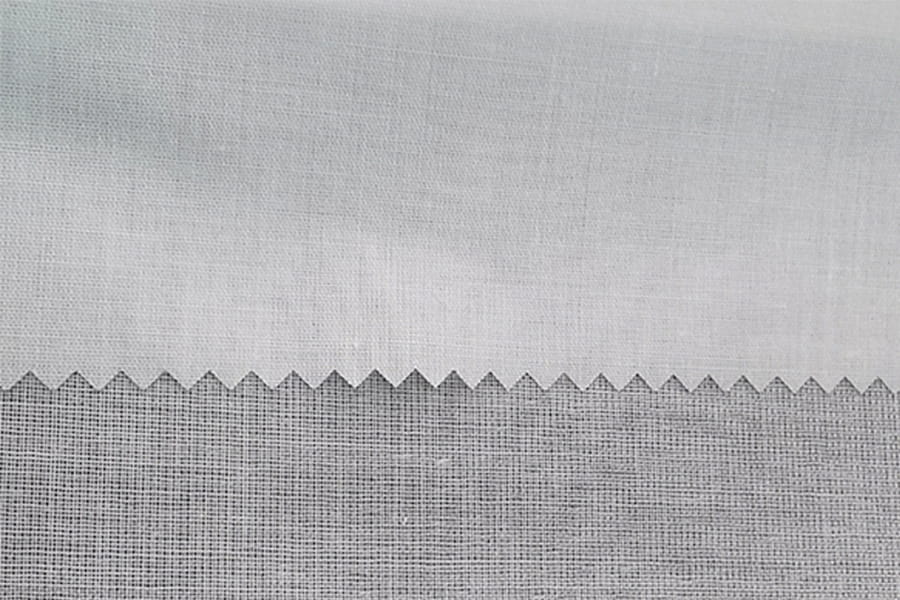

8. Available in Various Weights and Thicknesses

Polyester fusible interlining comes in a range of weights and thicknesses, offering greater flexibility in garment production. Whether you need lightweight interlining for delicate fabrics or a heavier option for structured garments, there is a fusible interlining to meet every need.

How It Works: The range of options available means that tailors can choose the best fusible interlining for their specific fabric, ensuring the right balance of softness, structure, and durability.

Example: For a flowing summer dress made from lightweight cotton, a thin fusible interlining would add a touch of structure without overpowering the fabric. For a tailored blazer, a thicker interlining would provide the necessary rigidity to maintain the sharpness of the jacket.

9. A Sustainable Option

As sustainability becomes an increasingly important consideration in fashion, eco-friendly polyester fusible interlining is gaining popularity. Many manufacturers now produce fusible interlining made from recycled polyester or eco-friendly materials, offering a more sustainable option for eco-conscious tailors and designers.

How It Works: These sustainable interlining options are produced using environmentally responsible methods, such as reducing water usage, minimizing waste, and sourcing materials from recycled fibers.

Example: A tailor who is committed to sustainable fashion can choose to use polyester fusible interlining made from recycled plastic bottles, reducing the overall environmental footprint of their garments.

10. Enhances Fabric Performance

Polyester fusible interlining not only improves the garment’s structure but also enhances its performance in terms of wrinkle resistance and shape retention. This is particularly important for garments that need to retain their form throughout the day or after multiple washes.

How It Works: The polyester fibers help the garment resist wrinkles and creases, keeping it looking fresh and crisp for longer periods. Additionally, the fusible interlining ensures that the fabric doesn’t lose its shape, even after hours of sitting, bending, or stretching.

Example: A business suit with fusible interlining will maintain its sharp lines and wrinkle-free appearance throughout a long day, reducing the need for frequent ironing or steaming

English

English 中文简体

中文简体 русский

русский Español

Español