In the textile industry, selecting the right knitted fabric is a critical decision that dictates the silhouette, comfort, and longevity of a garment. While there are dozens of knit varieties, Single Jersey and Interlock stand as the two pillars of weft knitting. Understanding their structural differences is not just a matter of technical curiosity—it is essential for ensuring that a fabric’s physical properties align with the intended use of the apparel.

1. Structure: Single-Knit vs. Double-Knit

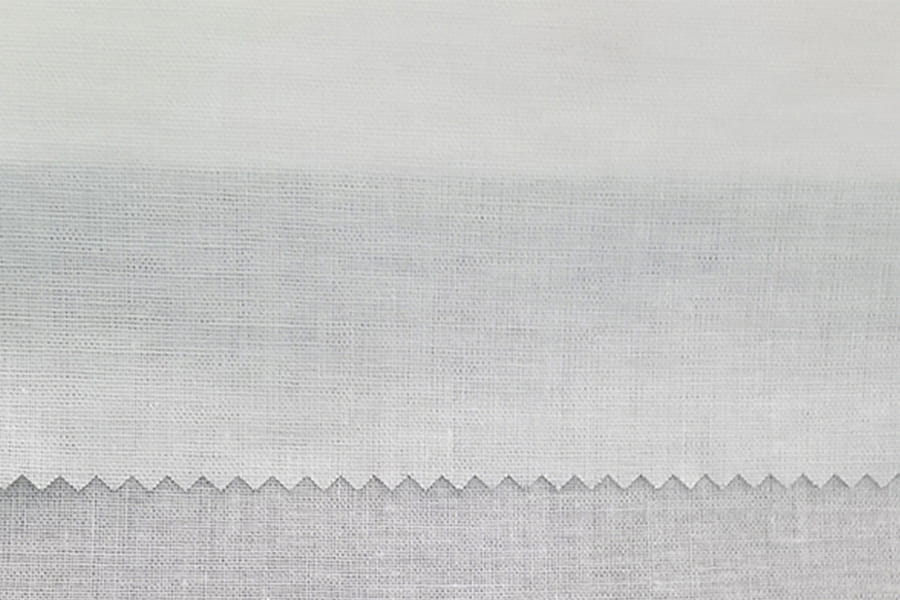

The most fundamental distinction between these two fabrics lies in their construction on the knitting machine. Single Jersey is produced using a single set of needles. This creates a fabric with a distinct “technical face” characterized by vertical V-shapes and a “technical back” featuring horizontal loops (half-moons). Because it consists of only one layer of loops, it is relatively thin and lightweight.

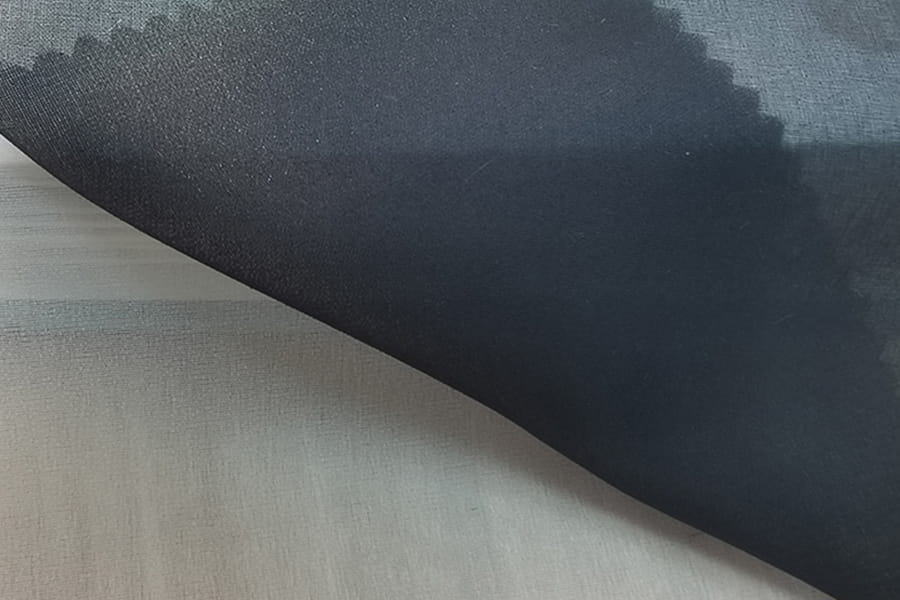

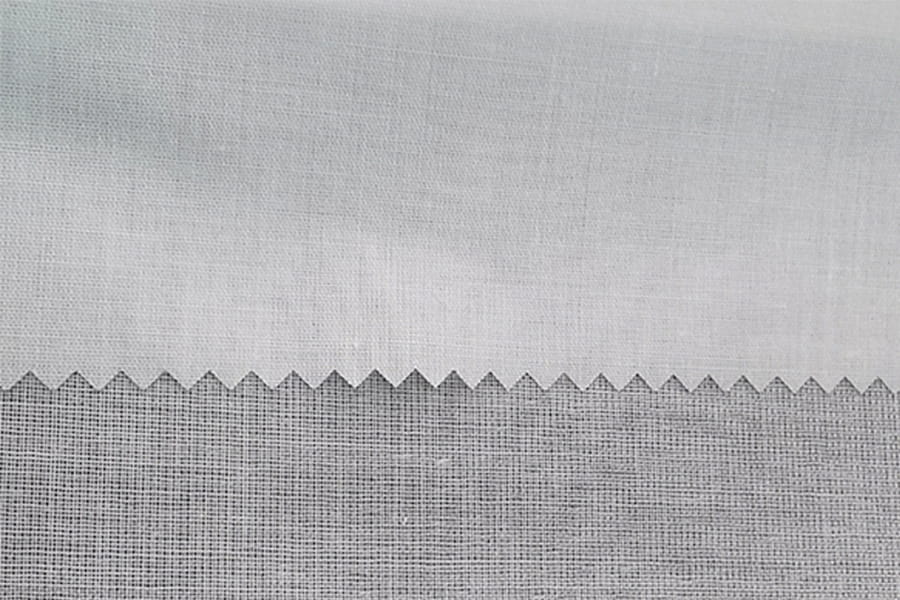

In contrast, Interlock is a category of double-knit fabric. It is manufactured using two sets of needles that work in synchronization to create two layers of jersey fabric knitted together back-to-back. The result is a “trapped” structure where the loops of one layer are aligned with the loops of the other. This unique interlocking mechanism means that the fabric looks identical on both the front and the back. If you pull a thread from an Interlock fabric, you are essentially pulling from a complex, integrated system that provides significantly more structural integrity than a single-layer knit.

2. Physical Properties: Weight, Stretch, and Stability

Because of its double-layered construction, Interlock is inherently heavier and denser than Single Jersey. A standard cotton jersey might weigh between 120–180 GSM (grams per square meter), whereas an Interlock fabric of the same yarn count will typically exceed 220–300 GSM.

When it comes to stretch, Single Jersey is known for its high degree of horizontal (crosswise) elasticity. However, it lacks “dimensional stability,” meaning it can easily become overstretched or saggy after prolonged wear. Interlock, while still possessing natural stretch due to the knit loops, offers superior “rebound” or recovery. Its double-knit structure acts like a spring system that pulls the fabric back to its original shape. Furthermore, Single Jersey is notorious for its “edge curl”—the tendency of the fabric to roll toward the face when cut. Interlock remains perfectly flat, making it a dream for garment manufacturers who require precision during the cutting and sewing stages.

3. Breathability vs. Thermal Insulation

The choice between these two fabrics often comes down to the climate and activity level of the wearer. Single Jersey is the undisputed champion of breathability. Its single-layer structure is more porous, allowing heat and moisture to escape the body rapidly. This is why it is the universal choice for basic T-shirts, summer dresses, and high-performance gym wear where ventilation is the priority.

Interlock, on the other hand, is a master of thermal regulation. The tiny air pockets trapped between the two integrated layers of the knit act as a natural insulator. This makes Interlock much warmer than Jersey, even when using the same fiber type. This warmth, combined with its exceptionally soft and “squishy” hand-feel, makes it the premium choice for baby clothing (which requires warmth and softness against delicate skin), high-end pajamas, and transitional loungewear for autumn and winter.

4. Durability and Longevity

In terms of industrial performance, Interlock is the more durable candidate. Because it is a double-knit, it is much less likely to “run” or develop “ladders” if a single thread is snagged. If a hole develops in a Single Jersey T-shirt, the tension in the single-knit loops causes the hole to expand rapidly along the vertical column. In an Interlock fabric, the second layer of loops provides a safety net that stabilizes the damage.

Furthermore, Interlock is less prone to pilling (the formation of small fiber balls on the surface). Its tight, interlocked weave keeps the fiber ends tucked inside the structure more effectively than the looser, more exposed loops of Single Jersey. While Single Jersey is cost-effective and perfect for “fast fashion” or lightweight basics, Interlock is an investment in quality, offering a garment that will maintain its opaque, crisp appearance through hundreds of wash cycles without losing its structural “memory.”

Comparison Table: Single Jersey vs. Interlock

| Feature | Single Jersey (Single-Knit) | Interlock (Double-Knit) |

|---|---|---|

| Visual Appearance | Distinct front (V) and back (U) | Reversible (Same on both sides) |

| Average Weight | 120 - 180 GSM (Lightweight) | 220 - 300+ GSM (Heavier) |

| Edge Stability | Curls significantly when cut | Remains flat and stable |

| Opacity | Can be sheer/translucent | Highly opaque (No see-through) |

| Stretch Recovery | Moderate (May lose shape) | High (Excellent recovery) |

| Common Uses | Standard T-shirts, underwear, leggings | Babywear, polos, hoodies, luxury knits |

FAQ Section

Q1: Can I use Single Jersey for baby clothes?

A: While possible for summer rompers, Interlock is generally preferred for babies. Its double-knit structure provides more warmth and is much softer on sensitive skin, plus it handles the frequent high-heat washing required for baby items better than Jersey.

Q2: Which fabric is better for printing (Screen print or DTG)?

A: Single Jersey is the industry standard for T-shirt printing because its surface is flatter and thinner, allowing ink to bond well. However, Interlock provides a more premium “canvas” for embroidery or high-end heat transfers because the fabric doesn’t pucker under the weight of the stitches.

Q3: Does Interlock shrink more than Single Jersey?

A: Generally, Interlock has better dimensional stability, but because it contains more fiber per square inch, the absolute shrinkage might feel more significant if not pre-shrunk. Always check the manufacturer’s shrinkage specifications for both.

References

- Spencer, D. J. (2025). “Knitting Technology: A Comprehensive Guide to Fabric Structures and Machinery.” Textile Institute Publications.

- Journal of Fiber Science and Technology. “Comparative Analysis of Thermal Resistance in Weft-Knitted Structures.”

- International Textile and Apparel Association (ITAA). “Durability Standards for Double-Knit vs. Single-Knit Consumer Goods.”

English

English 中文简体

中文简体 русский

русский Español

Español