Polyester fusible interlining is a versatile and widely used material in garment construction. It plays a key role in enhancing the structure, durability, and overall quality of clothing items.

1. Understanding Polyester Fusible Interlining

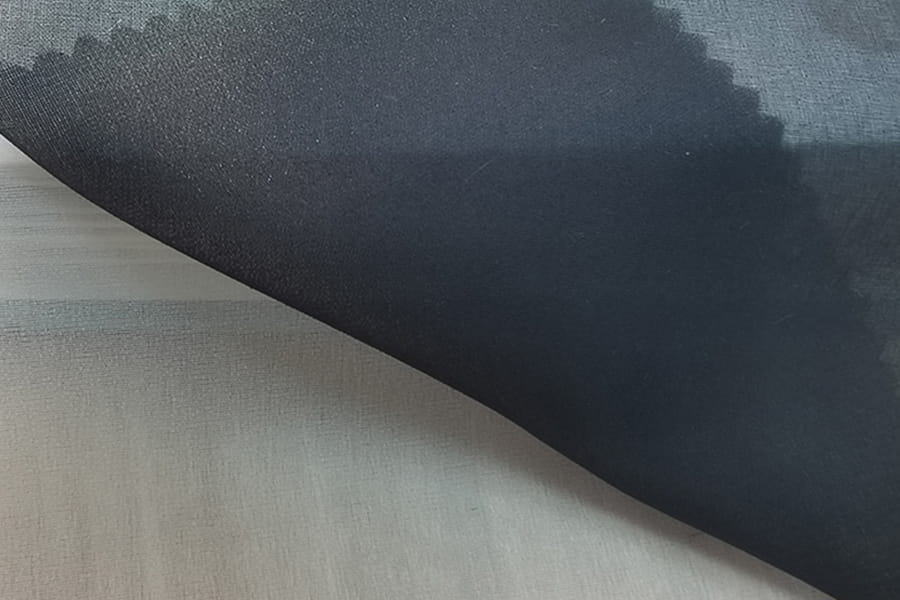

Polyester fusible interlining is a type of non-woven or woven fabric that is coated with an adhesive on one side. This adhesive allows it to bond with the fabric when heat is applied, creating a durable and stable layer. It is typically made from polyester fibers, which are known for their strength, flexibility, and resistance to shrinkage. The key feature that sets fusible interlining apart is its ability to fuse with the fabric through the application of heat, which forms a strong bond without the need for sewing or additional stitching.

Unlike traditional interlining, which relies on sewing or tacking to hold it in place, fusible interlining is fused directly to the fabric using a heat press, iron, or steam, making it a quicker and more efficient option.

2. How Is Polyester Fusible Interlining Used in Garment Construction?

Polyester fusible interlining is used in a variety of garment construction processes, especially when extra stiffness or structure is required. Here are the primary ways it is used:

a) Adding Structure to Soft Fabrics

In garments made from soft, lightweight fabrics like cotton, silk, or rayon, polyester fusible interlining is often used to provide structure. For instance, when making blouses, shirts, or dresses, fusible interlining is added to collar and cuff areas to prevent them from sagging and to help them maintain their shape.

b) Reinforcing Areas of High Stress

Polyester fusible interlining is also used to reinforce areas of garments that experience high stress or wear, such as waistbands, buttonholes, and pocket openings. By adding fusible interlining to these areas, the garment becomes more durable and can withstand regular use without stretching out or losing its shape.

c) Improving the Fit and Appearance

In tailoring and custom garment making, polyester fusible interlining is used to improve the overall fit and appearance of a garment. It can be fused to the inside of fabrics in places where extra support is needed, like around the shoulders, chest, and back. The interlining gives these areas a crisper, more professional look, contributing to the overall clean lines of the garment.

d) Creating Sharp Creases and Edges

For formalwear like suits or trousers, polyester fusible interlining can be used to create sharp creases, pleats, and edges that hold their shape over time. This is particularly useful in trousers, where a clean crease down the front is desired. The fusible interlining helps maintain the sharpness of these features even after repeated wear and washing.

3. Types of Polyester Fusible Interlining

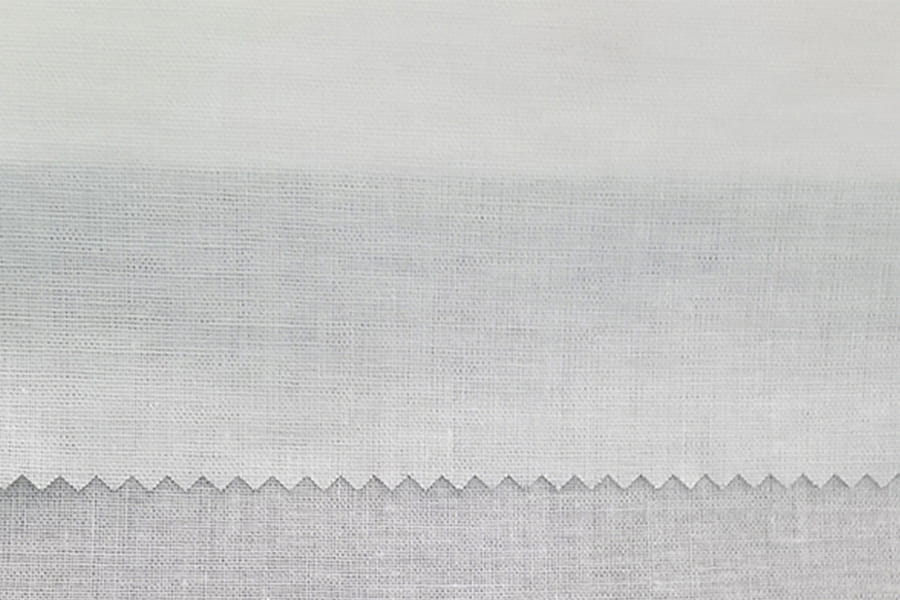

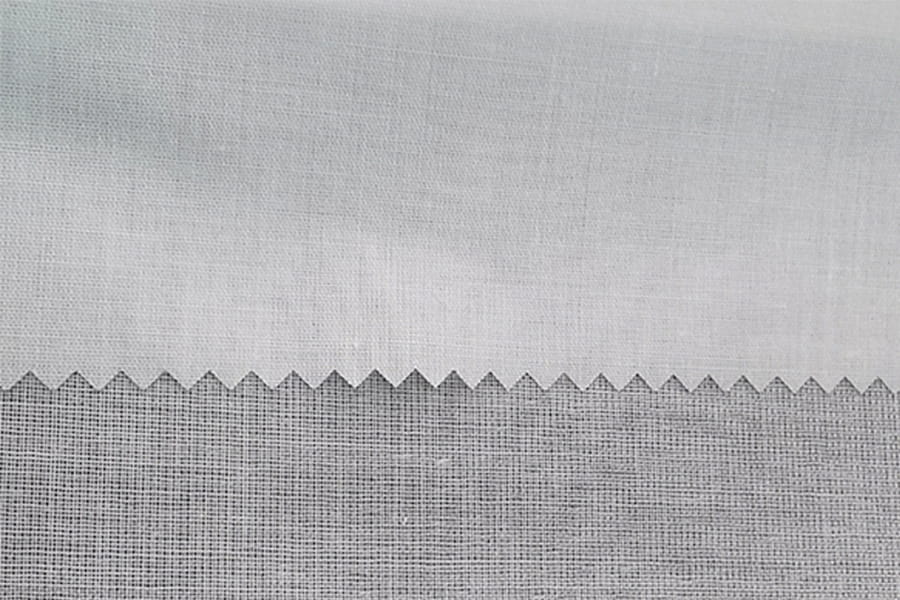

There are different types of polyester fusible interlining, each with specific characteristics suited to various applications:

-

Lightweight Fusible Interlining: Often used for delicate fabrics like silk or chiffon, lightweight fusible interlining adds minimal stiffness and is ideal for creating soft structure in garments like blouses, dresses, or skirts.

-

Medium-weight Fusible Interlining: This is one of the most commonly used types of fusible interlining and is perfect for most fabrics such as cotton, linen, and wool. It provides moderate stiffness and is great for reinforcing collars, cuffs, waistbands, and jacket fronts.

-

Heavyweight Fusible Interlining: Used for creating structure in heavy fabrics such as denim, tweed, and canvas, heavyweight fusible interlining adds a significant amount of firmness and support, often used in tailored coats, jackets, and other outerwear.

4. Advantages of Using Polyester Fusible Interlining

There are many benefits to using polyester fusible interlining in garment construction:

a) Time-Saving

One of the major advantages of fusible interlining is the time saved during the construction process. Since it doesn’t require sewing or tacking in place, the application is much quicker and easier compared to traditional interlining methods.

b) Durability

Polyester fibers are known for their strength and resilience, meaning garments with fusible interlining are more durable and resistant to wear and tear. The adhesive bond created during the fusing process ensures that the interlining stays in place even after repeated washing or dry cleaning.

c) Improved Fit and Structure

Fusible interlining helps to enhance the overall fit and structure of garments, giving them a more professional, polished appearance. It adds shape to soft fabrics, making them more comfortable and flattering to wear.

d) Versatility

Polyester fusible interlining can be used on a wide range of fabrics, from delicate silks to sturdy denims, making it a versatile choice for various types of garments. Whether you’re creating a light, airy blouse or a heavy winter coat, fusible interlining can meet the needs of both.

5. How to Apply Polyester Fusible Interlining

Applying polyester fusible interlining is a straightforward process. Here’s a step-by-step guide to ensure proper application:

-

Prepare the Fabric: Make sure the fabric is clean and free of wrinkles before applying the interlining.

-

Cut the Interlining: Cut the polyester fusible interlining to match the pattern piece you are working with (such as collar, cuff, or waistband).

-

Align the Interlining: Place the fusible side of the interlining against the wrong side of the fabric. Make sure it is positioned exactly where you want it.

-

Press with Heat: Using an iron set to the appropriate temperature (usually medium to high heat), press the interlining and fabric together. Apply firm pressure for about 10-15 seconds. Make sure to use steam or a damp pressing cloth for best results.

-

Allow to Cool: Let the fabric cool before moving or handling it to ensure the adhesive has fully set and the interlining is securely bonded.

FAQ

Q1: Can polyester fusible interlining be used on all fabrics?

Polyester fusible interlining is suitable for a wide range of fabrics, including cotton, silk, wool, and denim. It is important to choose the correct weight of interlining based on the fabric you are using.

Q2: How long does the bond last after applying fusible interlining?

The bond created by fusible interlining is long-lasting, even after multiple washes. However, the longevity depends on the quality of the interlining, the fabric, and proper application.

Q3: Can I machine wash a garment with fusible interlining?

Yes, garments with fusible interlining can typically be machine washed, but it is recommended to follow the care instructions provided with the interlining and fabric. To preserve the bond, it’s best to avoid high heat settings during drying.

Q4: What is the difference between fusible and non-fusible interlining?

The main difference is that fusible interlining has an adhesive on one side that bonds to the fabric when heat is applied, while non-fusible interlining requires sewing or tacking to keep it in place.

Q5: Can fusible interlining be used for other purposes besides garment making?

Yes, fusible interlining can also be used in home décor projects such as making curtains, cushions, and other upholstery items where additional structure and durability are needed.

References:

- Interfacing and Its Role in Garment Construction. Textile Institute, 2021.

- Understanding Fusible and Non-Fusible Interfacing. Sew Easy Tutorials, 2020.

English

English 中文简体

中文简体 русский

русский Español

Español