Introduction

Polyester fusible interlining is one of the most important materials in modern garment construction. For beginners, it may seem like a small detail, but using the right interlining can completely change the appearance and durability of your sewing projects. Fusible interlining is designed to add structure, support, and stability to fabrics, especially those that are lightweight or stretchy. Without it, garments may sag, wrinkle easily, or lose their shape after washing.Beginners often struggle with understanding which type of interlining to use and how to apply it properly. The good news is that polyester fusible interlining is user-friendly and suitable for a wide range of sewing projects, from shirts and blouses to dresses and jackets. Its adhesive layer allows it to bond directly to the fabric when heat is applied, eliminating the need for complicated stitching techniques.

In addition to adding structure, interlining can also enhance the professional appearance of garments. For example, collars, cuffs, and waistbands often require a firmer fabric to maintain crisp lines. Using the wrong type or skipping interlining can make even high-quality fabric look flimsy or unfinished.

1. What is Polyester Fusible Interlining?

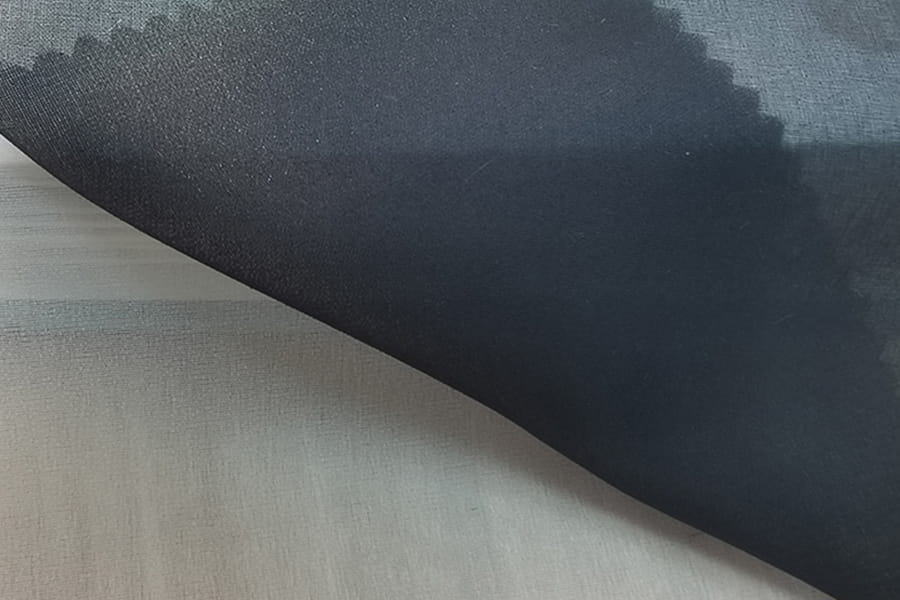

Polyester fusible interlining is a fabric with a unique adhesive layer that bonds to other fabrics when heat is applied. It is lightweight, flexible, and available in different thicknesses, making it highly versatile for a variety of sewing applications. Unlike traditional sew-in interlining, which requires stitching to attach, fusible interlining adheres directly to the fabric, saving time and effort for beginners.Key Features of Polyester Fusible Interlining

Easy to Apply

One of the main advantages of polyester fusible interlining is its ease of use. Beginners can simply place the adhesive side on the wrong side of the fabric and press with a warm iron to bond the layers together. This eliminates the need for complex stitching or hand-sewing, making it ideal for home sewing projects.Adds Structure and Support

Some fabrics, especially lightweight or stretchy materials, lack natural support. By adding fusible interlining, garments maintain their shape, preventing sagging, wrinkling, or uneven seams. For example, collars and cuffs look much sharper and maintain crisp lines with the right interlining.Versatile Applications

Polyester fusible interlining is suitable for shirts, blouses, skirts, dresses, jackets, and even home décor projects like curtains or cushions. Its versatility makes it a staple in both professional tailoring and hobby sewing.How It Works

The interlining contains a heat-activated adhesive that melts and bonds with the main fabric when ironed. After cooling, the adhesive solidifies, creating a firm connection between the layers. This process is simple but requires attention to detail, including correct temperature, pressing time, and alignment, to achieve a smooth and wrinkle-free finish.Why Beginners Should Start with Polyester Fusible Interlining

For beginners, using fusible interlining reduces the risk of errors and improves overall sewing confidence. It eliminates the need for precise hand-stitching while providing professional-looking results. Learning to use this material effectively lays a strong foundation for more advanced sewing techniques in the future.

2. Types of Polyester Fusible Interlining

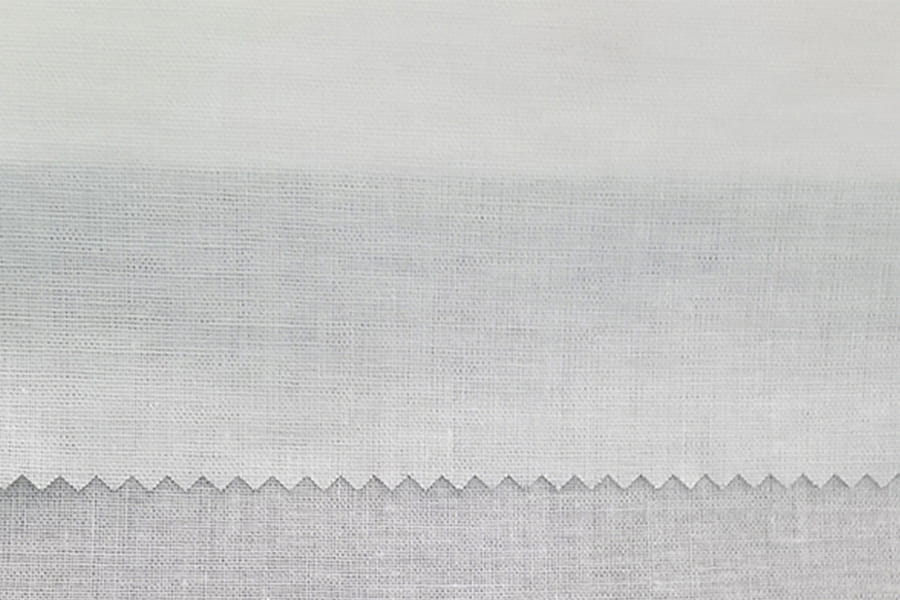

Polyester fusible interlining comes in different weights and types, each designed for specific fabrics and purposes. Understanding these types is essential for beginners to choose the right interlining for each project.Lightweight Interlining

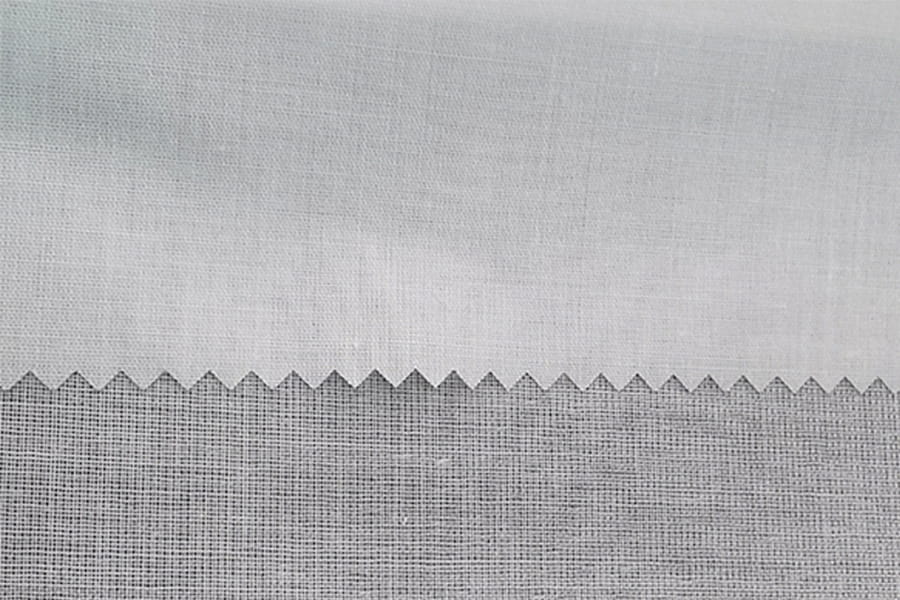

Lightweight interlining is thin and flexible, making it ideal for delicate fabrics such as chiffon, silk, or lightweight cotton. It provides enough structure to maintain shape without adding bulk. Shirts, blouses, and summer dresses are common applications. Beginners should always test lightweight interlining on a scrap fabric piece first to ensure smooth adhesion and avoid visible stiffness.Medium-weight Interlining

Medium-weight interlining offers a balance between structure and flexibility. It is suitable for skirts, casual jackets, and dresses where moderate support is required. This type provides more stability than lightweight interlining but is still easy to work with for beginners. It helps garments maintain form while allowing comfortable movement.Heavyweight Interlining

Heavyweight interlining is thick and firm, ideal for coats, jackets, and tailored garments that require substantial structure. While more challenging to apply due to its thickness, it ensures garments hold their shape even under daily wear. Beginners should use a pressing cloth and apply appropriate heat to avoid damaging the fabric.Other Considerations

In addition to weight, fusible interlining may vary by adhesive type. Some interlinings have a full-adhesive coating, while others have a partial coating for easier repositioning. Choosing the right type depends on the fabric, garment design, and your comfort level with pressing techniques.

3. How to Choose the Right Interlining

Selecting the right polyester fusible interlining requires careful consideration of several factors. Beginners often make the mistake of using a single type for all projects, which can lead to poor results.Consider Fabric Type

Lightweight fabrics such as chiffon or fine cotton require lightweight interlining to prevent stiffness. Medium fabrics like linen or polyester blends work well with medium-weight interlining. For heavy fabrics such as wool or denim, heavyweight interlining is necessary to maintain structure.Purpose of the Garment

The intended function of the garment affects interlining choice. For example, a professional shirt collar requires firm interlining to stay crisp, while a flowy dress benefits from softer, lightweight interlining for flexibility.Adhesive Type

Some polyester fusible interlinings are iron-on, requiring heat for bonding. Others may require additional stitching for security. Beginners should prioritize iron-on interlining for ease of use, especially when starting with basic sewing projects.Testing Before Use

Always test the interlining on a fabric scrap before applying to the actual garment. Check for wrinkling, stiffness, or adhesive bleeding, which may affect the final appearance. This step prevents mistakes and ensures smooth, professional results.

English

English 中文简体

中文简体 русский

русский Español

Español