In today’s apparel industry, functional lining fabrics are not only used to enhance comfort and durability, but they also play a crucial role in improving the overall performance and value of garments. Whether it’s to meet consumer needs for comfort, breathability, water resistance, or to increase brand competitiveness, selecting the right lining fabric is essential.

1. Understanding the Different Types of Functional Lining Fabrics

Functional lining fabrics come in a variety of types, each serving unique functions and applications. Each fabric has its own advantages and limitations, so businesses must choose the most appropriate one based on their specific product needs. Below are the common types of functional lining fabrics:

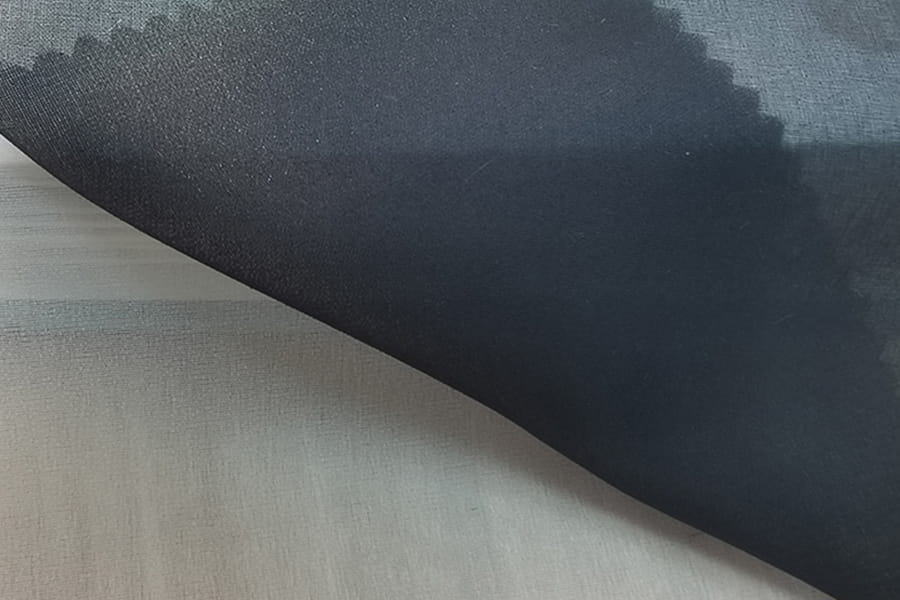

Waterproof Fabrics

Waterproof fabrics are typically used for products that need to prevent water penetration, such as raincoats, outdoor gear, and waterproof jackets. These fabrics are usually treated with special coatings or membranes to keep garments dry in rainy or snowy weather. For example, polyurethane (PU) coated fabrics and GORE-TEX® membranes are popular waterproof materials. Waterproof fabrics offer strong water resistance but may sacrifice some breathability, so it’s important to strike a balance between waterproofing and breathability when making a selection.

Breathable Fabrics

Breathable fabrics are commonly used in sportswear, casual wear, and garments that require good air circulation. Breathable fabrics help wick away moisture, keeping the skin dry and comfortable. Polyester and nylon fabrics are typical breathable materials, allowing air to circulate between fibers while maintaining durability and lightness.

Antibacterial Fabrics

Antibacterial fabrics are primarily used to prevent bacterial growth and keep garments hygienic. These fabrics are often treated with antimicrobial agents, making them ideal for products like underwear, socks, sportswear, and medical apparel. Antibacterial fabrics are highly effective in preventing odor and bacterial build-up, making them perfect for prolonged wear.

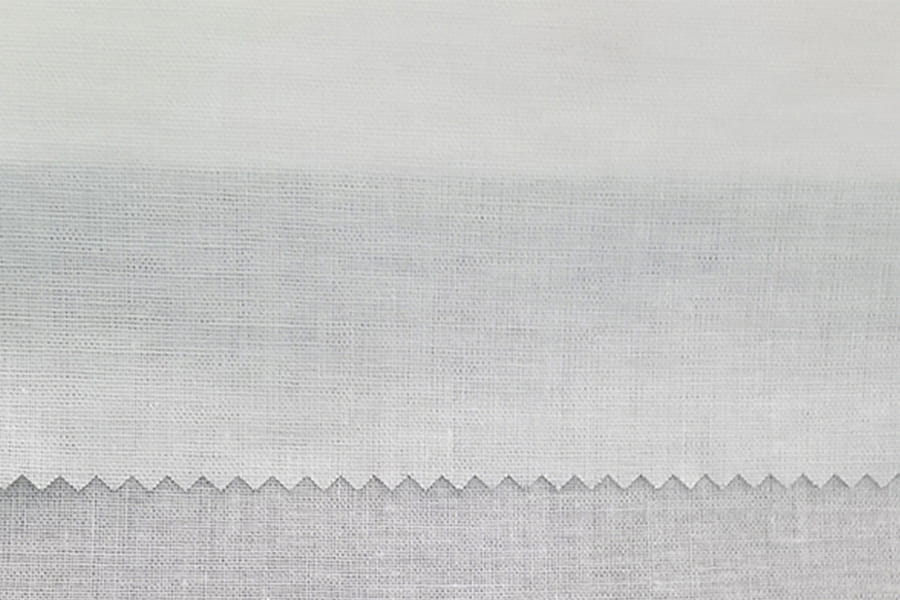

Wrinkle-Resistant Fabrics

Wrinkle-resistant fabrics are ideal for formal garments such as suits, shirts, and skirts. These fabrics are specially treated to retain their shape and appearance even after washing, reducing the need for ironing. Polyester and blended fabrics are commonly used for their wrinkle-resistant properties, offering both durability and lasting aesthetics.

Insulating Fabrics

Insulating fabrics are used in winter garments such as down jackets, coats, and outerwear to trap body heat and provide warmth. These fabrics use advanced insulation techniques, such as heat-reflective layers or thermal linings, to maintain body temperature in cold environments. Popular insulating materials include polyester fibers, wool blends, and high-performance thermal fibers.

2. Evaluating Fabric Comfort and Adaptability

Comfort is one of the core factors in selecting functional lining fabrics. While each fabric type has its own advantages, only those that provide a comfortable wearing experience will meet consumer expectations. When businesses procure functional lining fabrics, they should evaluate the following aspects:

Fabric Softness

The softness of the fabric directly affects comfort. Softer fabrics are better at conforming to the skin and reducing friction, preventing discomfort. Soft lining fabrics are ideal for garments that come into direct contact with the skin, such as underwear, activewear, and loungewear.

Breathability and Moisture Management

Good breathability allows moisture to evaporate, keeping the skin dry. This is especially important in sportswear, where sweat management is critical. When selecting lining fabrics, businesses should check for good airflow and moisture-wicking properties. Not only does this enhance comfort, but it also helps prolong the life of the garment.

Fabric Adaptability

Adaptability refers to how well a fabric performs in various environmental conditions, such as temperature and humidity. High-quality functional lining fabrics adapt to different external environments—insulating fabrics provide warmth in cold weather, while breathable fabrics keep comfort in hot climates.

3. Considering Garment Usage and Performance Requirements

When selecting functional lining fabrics, businesses need to consider the garment’s intended use and specific performance needs. For example, the requirements for sportswear, outdoor gear, and business attire differ significantly, and each needs a fabric that meets its functional demands.

Sportswear

Sportswear requires high levels of flexibility, breathability, and moisture-wicking capabilities. These functional fabrics help athletes stay dry and avoid discomfort due to trapped sweat. Common lining fabrics for sportswear include polyester, nylon, and Lycra, all of which offer stretchability and breathability.

High-End Fashion Apparel

High-end fashion apparel places a greater emphasis on fabric appearance, texture, wrinkle-resistance, and durability. Functional fabrics also have a significant role in the high-end market, especially for garments that need to enhance comfort or showcase unique features.

Outdoor Gear

Outdoor gear fabrics need to provide multiple functionalities, such as water resistance, wind resistance, and insulation. High-performance functional lining fabrics are crucial to ensure that wearers remain comfortable and safe in extreme environments. For example, GORE-TEX® fabrics are commonly used in outdoor garments for their waterproof and breathable properties.

4. Fabric Sustainability and Environmental Considerations

With the growing awareness of environmental issues, many businesses are now paying attention to the sustainability and eco-friendliness of the fabrics they use. Consumers are increasingly interested in environmentally responsible products, and many brands have started opting for recyclable and sustainably produced fabrics. This trend not only aligns with eco-conscious values but also improves brand image and market competitiveness.

Recycled Fabrics

Recycled fabrics help reduce resource waste and promote a circular economy. For instance, recycled polyester (rPET) is a widely used eco-friendly fabric made from plastic bottles or old garments. It reduces environmental impact while offering similar performance to virgin materials.

Organic Materials

Organic cotton, hemp, bamboo fibers, and other natural materials are excellent examples of sustainable fabrics. These materials are free from harmful chemicals, have a smaller environmental footprint, and reduce water and land usage during production.

5. Considering Cost-Effectiveness

In addition to quality, businesses must consider cost-effectiveness when selecting functional lining fabrics. Fabric price directly influences the final cost of the product, so it’s essential to balance quality and cost.

Balancing Fabric Price and Quality

High-quality functional lining fabrics tend to be more expensive, but they can significantly improve the garment’s overall performance and consumer experience. When procuring fabrics, businesses should balance the fabric’s price with market demands and product performance. This helps avoid excessive costs that could reduce a product’s competitiveness in the market.

6. Supplier Selection and Quality Control

Choosing a reliable supplier is crucial for ensuring the quality of functional lining fabrics. When procuring fabrics, businesses should prioritize suppliers with good reputations and solid experience. Establishing long-term relationships with suppliers ensures consistent product quality and better service, especially for custom requirements.

The Importance of Quality Control

Whether producing in bulk or customizing products, rigorous quality control is essential. Businesses should communicate clearly with suppliers about quality standards and request relevant test reports to ensure that the fabrics meet the required specifications.

Functional Lining Fabrics Procurement Comparison

| Fabric Type | Functional Features | Application Scenarios | Pros and Cons |

|---|---|---|---|

| Waterproof Fabrics | Water-resistant, durable | Outdoor wear, rain gear | Pros: Strong waterproofing; Cons: Poor breathability |

| Breathable Fabrics | Excellent breathability, moisture-wicking | Sportswear, casual wear | Pros: Comfortable; Cons: Not suitable for cold weather |

| Antibacterial Fabrics | Antibacterial, odor prevention | Underwear, sportswear, socks | Pros: Hygienic, healthy; Cons: Higher treatment costs |

| Wrinkle-Resistant Fabrics | Wrinkle-resistant, maintains appearance | Suits, shirts, formal wear | Pros: Time-saving, low maintenance; Cons: Prone to aging |

| Insulating Fabrics | Thermal insulation, heat retention | Winter jackets, down coats | Pros: Excellent warmth; Cons: Bulky |

English

English 中文简体

中文简体 русский

русский Español

Español