In the global textile industry, knit fabric has evolved from a simple material for hosiery into the most dominant force in modern apparel and technical textiles. Its unique combination of elasticity, moisture-wicking properties, and soft hand-feel makes it the preferred choice for everything from high-performance athletic wear to luxury loungewear. Unlike woven fabrics, which rely on a rigid interlacing of vertical and horizontal yarns, knit fabric is constructed through a sophisticated system of intermeshing loops. This fundamental mechanical difference allows knitwear to adapt to the contours of the human body, providing unparalleled comfort and freedom of movement. For designers, sourcing agents, and manufacturers, a deep understanding of knit construction is not merely a technical requirement—it is a strategic advantage.

The Structural Science: How Knit Fabric Differs from Woven Textiles

The primary differentiator in textile engineering lies in the “intermeshing” of yarns. While woven fabrics are defined by their stable, grid-like structure (the intersection of warp and weft), knit fabrics are built from one or more continuous yarns formed into interlocking loops. This “loop-based” geometry is the source of all the functional characteristics that define knitwear in the modern market.

The Mechanics of Stretch, Recovery, and Air Permeability

The most commercially significant characteristic of knit fabric is its mechanical stretch. Because each stitch consists of a loop, there is inherent physical “slack” within the fabric structure. When the material is pulled, the loops flatten and elongate, allowing the fabric to expand without breaking the fibers. However, in the high-end apparel sector, “stretch” is only half of the equation; recovery is equally critical. Premium knits are often engineered with a blend of natural fibers and synthetic elastomers like Spandex or Lycra. This ensures that after the stress of movement is removed, the fabric returns to its original dimensions, preventing the dreaded “bagging” effect at the knees or elbows. Furthermore, the interstitial spaces between the loops provide natural air permeability. This porosity makes knit fabrics inherently more breathable than tightly woven materials, which is why they are the standard for base layers and “Activewear” where thermal regulation and moisture management are paramount for the end-user.

Weft Knitting vs. Warp Knitting: The Two Pillars of Production

In industrial textile manufacturing, knits are divided into two distinct technological families based on the direction of loop formation.

- Weft Knitting: This is the most common method, where loops are formed horizontally across the width of the fabric. In this process, a single yarn can create an entire row (or “course”). This method is highly versatile and is used to produce Jersey, Rib, and Interlock fabrics. While weft knits offer superior softness and drapability, they are susceptible to “ladders” or running if a single loop is broken.

- Warp Knitting: This is a more complex, high-speed industrial process where yarns run vertically (along the “wale”) and are zigzagged together. Warp knits, such as Tricot and Raschel, are characterized by their extreme stability and resistance to unravelling. Because the loops are interlocked vertically, these fabrics are incredibly durable and are frequently utilized in technical applications, including swimwear, automotive upholstery, and medical textiles. Understanding the distinction between these two methods is essential for selecting a fabric that balances cost, speed of production, and structural integrity.

Common Types of Knit Fabric and Their Industrial Applications

The utility of a knit fabric is determined by its “Technical Specification,” specifically its weight, density, and the number of layers in its construction. In the manufacturing sector, these factors are measured in GSM (Grams per Square Meter). Choosing the correct knit type is a balancing act between the aesthetic requirements of the design and the physical demands of the garment’s intended use.

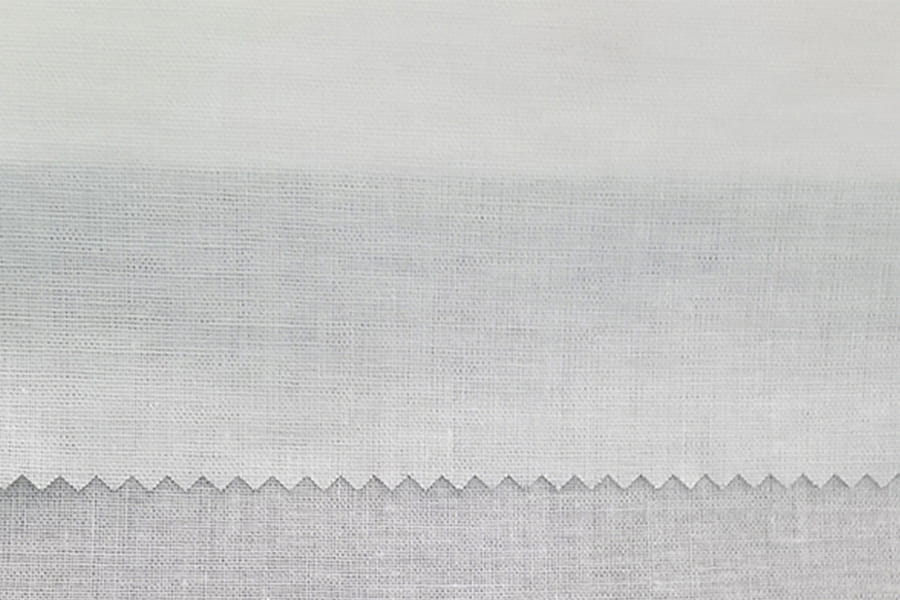

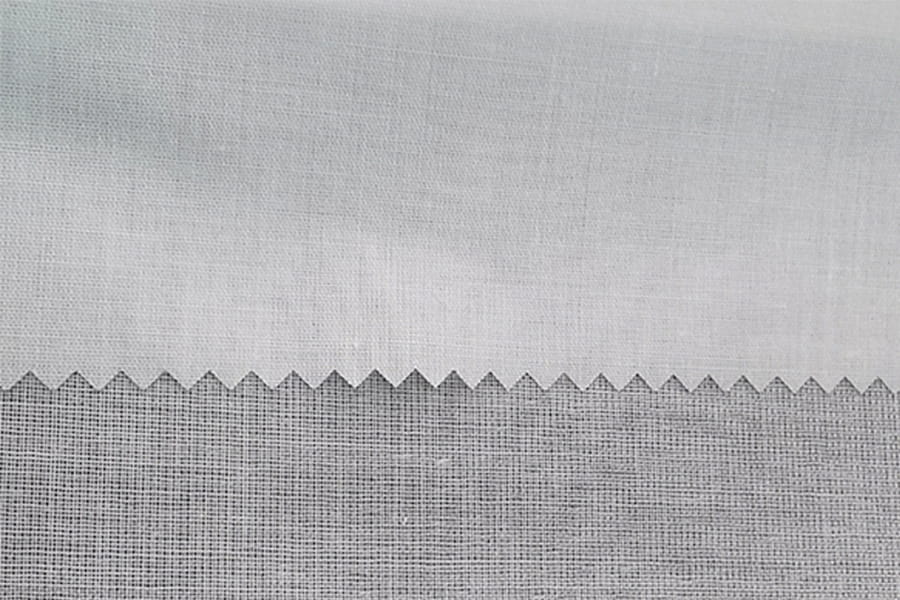

Jersey and Rib Knits: The Foundation of Global Apparel

Single Jersey is the most widely produced knit fabric in the world. Its defining feature is the clear distinction between its face and back; the face shows a neat “V” pattern (the knit stitch), while the back shows a “wave” or “bump” pattern (the purl stitch). It is lightweight, possesses an elegant drape, and is the universal standard for T-shirts and lightweight dresses. However, the single-layer construction makes it prone to “edge curling,” which can complicate the automated cutting and sewing processes in a factory setting.

Rib Knits, by contrast, utilize alternating knit and purl stitches to create vertical ridges. This structural “corrugation” provides maximum crosswise elasticity. Consequently, rib knits are the preferred material for “Trim Components”—cuffs, collars, and waistbands—where a snug, elasticated fit is required to seal out the elements or maintain the garment’s silhouette. For designers, mastering the use of different rib gauges (1x1 vs 2x2) is key to creating garments with professional-grade finishing.

Interlock and Double Knits: Stability and Luxury Performance

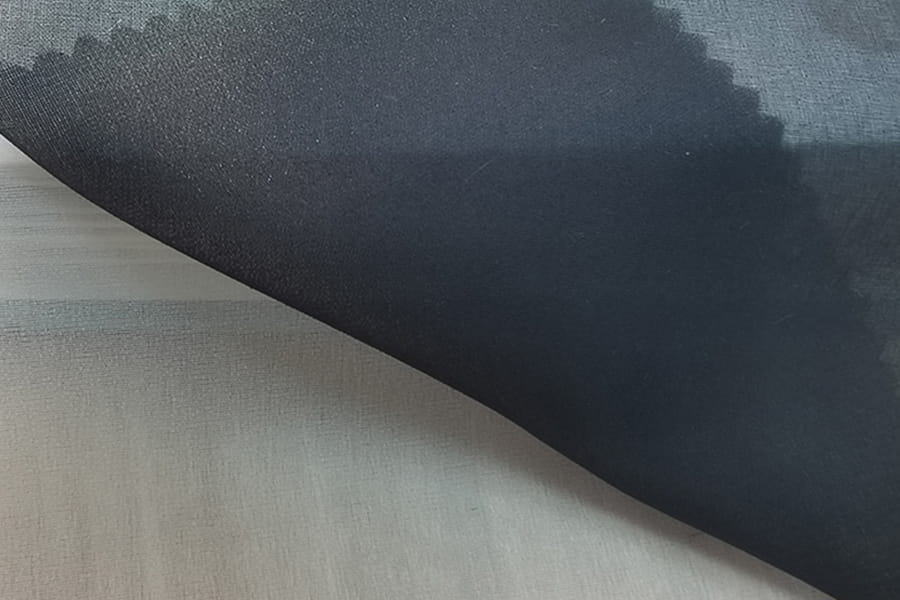

For applications requiring a more substantial feel and higher durability, Interlock and Double Knits are the industry benchmarks. Interlock is essentially two layers of jersey knitted together simultaneously, sharing the same set of yarns.

- Dual-Sided Smoothness: Unlike single jersey, interlock is smooth on both sides, offering a luxury hand-feel and a more opaque appearance.

- Dimensional Stability: Because it is a double-knit construction, it does not curl at the edges and is much more stable during the manufacturing process.

- Industrial Utility: These characteristics make it ideal for high-quality polo shirts, baby clothes (due to its softness and durability), and technical “Athleisure” pieces. For brands targeting the mid-to-high-end market, moving from single jersey to a 240+ GSM interlock is one of the most effective ways to increase perceived value and garment longevity.

Technical Comparison of Knit Fabric Specifications

This table provides a data-driven comparison of the most common knit fabrics used in the global garment industry.

| Fabric Type | Stitch Construction | Elasticity Profile | Typical GSM | Recommended Use Cases |

|---|---|---|---|---|

| Single Jersey | Weft (Knit Face/Purl Back) | High 2-Way Stretch | 120 - 180 | T-shirts, Loungewear, Linings |

| Interlock | Double Weft (Knit both sides) | Moderate Stability | 220 - 320 | Polo Shirts, Sportswear, Infant wear |

| Rib Knit | Weft (Alternating Wales) | Maximum Cross-stretch | 180 - 280 | Cuffs, Collars, Form-fitting tops |

| Tricot | Warp (Vertical Zigzag) | Stable / Low Run | 150 - 250 | Swimwear, Lingerie, Technical linings |

| French Terry | Weft (Looped Back) | Low / Moderate | 280 - 450 | Sweatshirts, Hoodies, Joggers |

Frequently Asked Questions (FAQ)

What is the difference between “Wales” and “Courses” in knit fabric?

In the world of knitting, “Wales” refer to the vertical columns of loops, similar to the warp in weaving. “Courses” are the horizontal rows of loops, similar to the weft. Understanding this grid is vital for correct fabric orientation during the cutting process to ensure the stretch aligns with the body’s movement.

Why do knit fabrics shrink more than woven fabrics?

The looped structure of a knit provides more “free space” for fibers to contract when exposed to heat and moisture during laundering. It is an industry standard to allow for a 5% to 8% shrinkage rate in knitwear, and professional manufacturers often “relax” the fabric for 24 hours before cutting to minimize dimensional changes in the final product.

Is knit fabric suitable for formal tailoring?

Traditionally, knits were seen as too casual for tailoring. However, “Ponte di Roma” (a heavy double-knit) has become a staple in modern formal wear. It offers the structured look of a woven fabric while providing the comfort and crease resistance of a knit, making it perfect for travel-friendly suits and blazers.

Technical References and Industrial Standards

- ASTM D3787: Standard Test Method for Bursting Strength of Textiles - Ball Burst Test.

- ISO 12945-2: Determination of fabric propensity to surface pilling and fuzzing.

- AATCC 135: Dimensional Changes of Fabrics after Home Laundering (Shrinkage Standards).

- Textile Institute Monographs: “Principles of Knitting Technology” - Comprehensive guide to warp and weft mechanics.

English

English 中文简体

中文简体 русский

русский Español

Español