Shrinkage is the Achilles’ heel of the textile world, and if you have ever pulled a once-perfect sweater out of the wash only to find it fits a toddler, you know the frustration firsthand. While all textiles are prone to some level of size change, Knitted Fabric is notorious for shrinking significantly more than its woven counterparts.

For fashion brands, garment manufacturers, and consumers alike, understanding the “why” behind this phenomenon is the first step toward preventing it.

1. The Science of the Loop: Why Knits Shrink

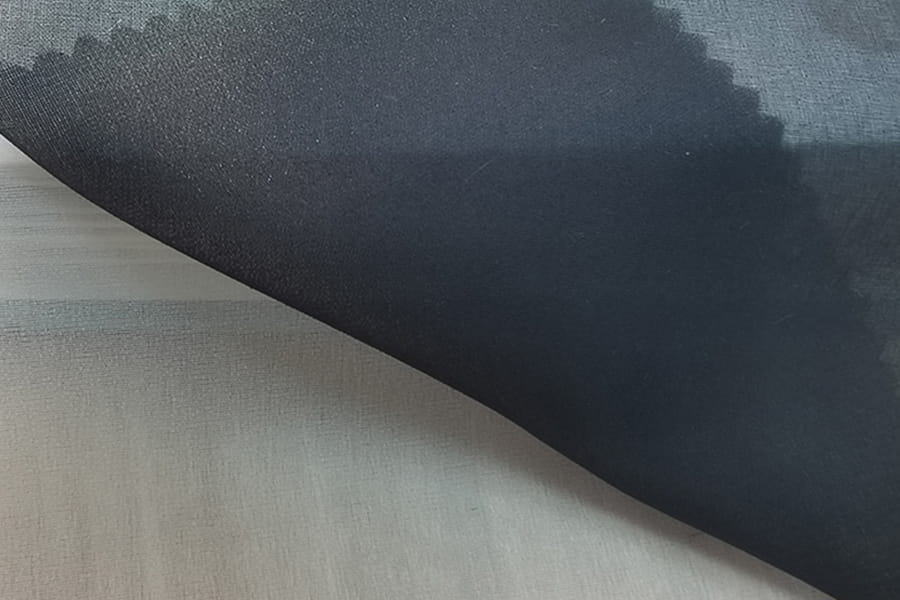

The primary reason Knitted Fabric shrinks more than other textiles lies in its unique construction. Unlike woven fabrics, where yarns are interlaced in straight lines (warp and weft), knitted fabrics are made of a continuous series of interlocking loops.

1.1 Mechanical Tension Release (Relaxation Shrinkage)

During the manufacturing process—knitting, dyeing, and finishing—the fabric is under constant tension. The loops are stretched out and elongated. When the fabric is immersed in water and agitated, the tension is released. The loops “relax” and return to their original, rounder, and more compact shape. Because the loops have more “room” to move than straight woven yarns, the resulting change in size is much more dramatic.

1.2 The Nature of the Fiber (Swelling Shrinkage)

Many knitted garments are made from natural fibers like cotton or wool. When these fibers get wet, they swell. In a knitted structure, this swelling forces the loops to rearrange themselves, usually by pulling the surrounding loops closer together. This is why a 100% cotton Knitted Fabric can shrink up to 10% in its first wash.

1.3 Felting (Specific to Wool/Protein Fibers)

For wool knits, shrinkage is often caused by “felting.” Wool fibers have microscopic scales. Heat, moisture, and agitation cause these scales to lock together like a zipper, pulling the fabric into a dense, thick, and permanently smaller mass.

2. Knitted vs. Woven: A Shrinkage Comparison

To put things into perspective, let’s look at how Knitted Fabric behaves compared to other common textiles under standard washing conditions.

Typical Shrinkage Rates by Construction

| Fabric Type | Construction | Estimated Shrinkage | Reason |

|---|---|---|---|

| Jersey / Rib | Knitted | 5% - 10% | Loop relaxation & fiber swelling |

| Denim / Poplin | Woven | 2% - 3% | Tight interlacing restricts movement |

| Polyester Knit | Knitted | 1% - 2% | Synthetic fibers are heat-set |

| Wool Sweater | Knitted | Up to 25% | Felting and scale interlocking |

3. How Manufacturers Can Prevent Shrinkage

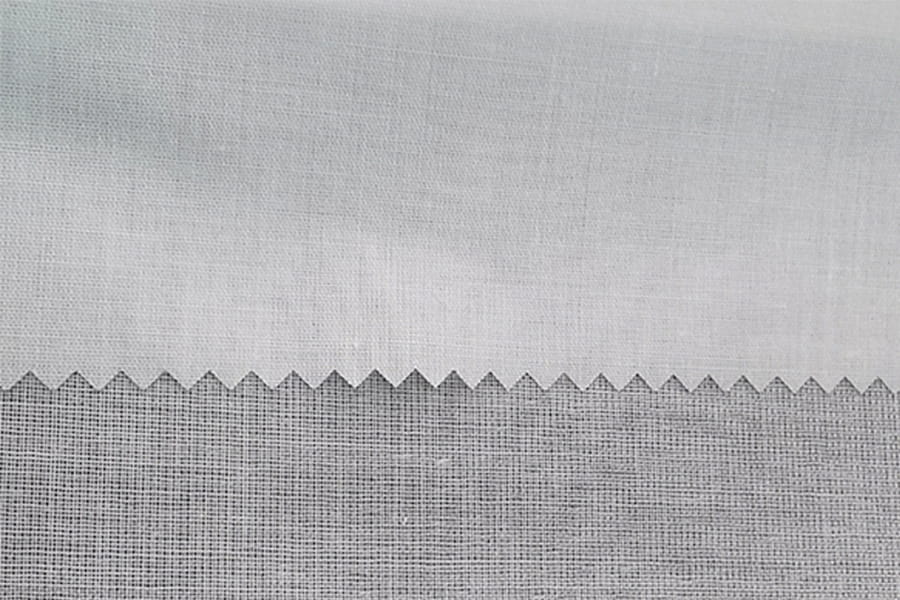

For B2B buyers and garment manufacturers, controlling shrinkage starts at the factory level. High-quality Knitted Fabric should undergo several stabilizing processes before it reaches the cutting table.

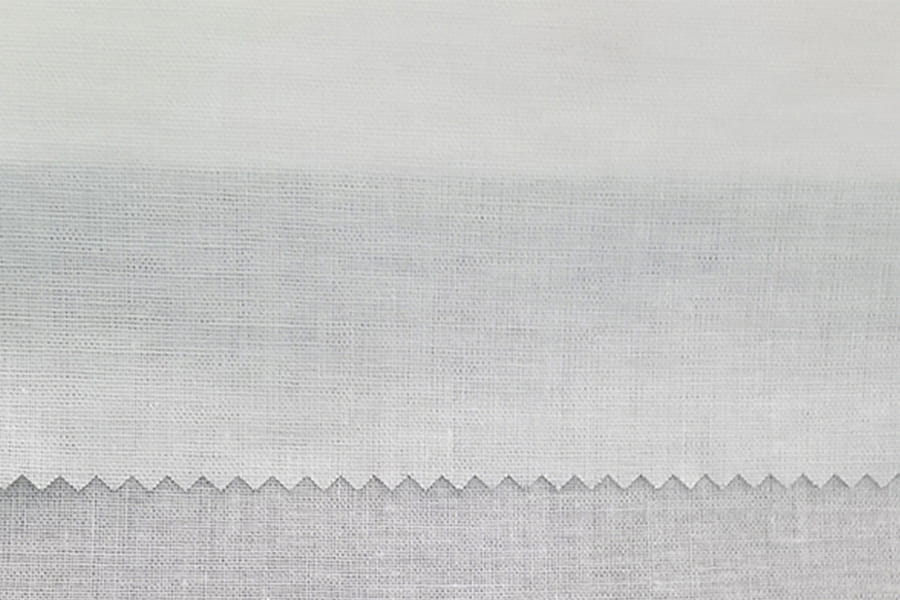

3.1 Pre-Shrinking (Compacting)

Manufacturers use a machine called a “compactor” to mechanically force the fabric loops into their relaxed state before the fabric is sold. This ensures that the majority of the “relaxation shrinkage” happens at the mill, not in the customer’s laundry room.

3.2 Heat Setting

For synthetic blends (like Cotton/Spandex), heat setting is crucial. The fabric is passed through a stenter frame at high temperatures, which “locks” the fibers into their current dimensions. This provides excellent dimensional stability.

3.3 Resin Treatments

Some cotton knits are treated with specialized resins that cross-link the cellulose fibers, preventing them from swelling and shifting during the wash cycle.

4. Consumer Tips: How to Prevent Shrinkage at Home

If you are working with or wearing Knitted Fabric, follow these “Golden Rules” to keep the dimensions stable:

- Cold Water Only: Heat is the catalyst for loop relaxation. Washing in cold water (30°C or below) keeps the fibers in their manufactured state.

- Avoid the Tumble Dryer: The combination of heat and mechanical tumbling is the fastest way to shrink a knit. Air drying flat is the safest method to maintain the garment’s shape.

- Use a Delicate Cycle: High-speed agitation can mechanically pull loops tighter. A gentle or hand-wash cycle reduces the stress on the fabric.

- Read the GSM: Generally, a higher GSM (Grams per Square Meter) indicates a denser knit, which may offer slightly better dimensional stability than very loose, “gauze-like” knits.

5. Is Shrinkage Inevitable?

While all knitted fabrics have a natural tendency to shift, it is not inevitable. By choosing fabrics that have been properly compacted and heat-set, and by following strict care guidelines, the impact of shrinkage can be minimized to less than 2%.

Understanding that a knit is essentially a “network of springs” (loops) helps in treating the material with the care it needs to last for years without losing its fit.

FAQ: Frequently Asked Questions

Q1: Can I “un-shrink” a knitted garment?

A: To an extent. You can soak the garment in lukewarm water with hair conditioner (to lubricate the fibers) and gently stretch it back to shape while damp. However, this is difficult to do evenly and won’t work on felted wool.

Q2: Which knit type shrinks the least?

A: Synthetic knits like 100% Polyester or Nylon shrink the least because the fibers do not swell in water. Among natural fibers, “Interlock” knits are generally more stable than “Single Jersey.”

Q3: Does expensive knitted fabric shrink less?

A: Not necessarily. Even the most expensive 100% organic cotton will shrink if not pre-treated. Quality is determined by how the manufacturer handles the finishing and pre-shrinking processes, not just the price of the fiber.

References

- Textile Testing: Dimensional Stability to Washing and Drying (AATCC Test Method 135).

- Principles of Knitting: Technology and Structures, Samuel Raz.

- Shrinkage Control of Cotton Knitted Fabrics, Journal of Textile and Apparel, Technology and Management.

English

English 中文简体

中文简体 русский

русский Español

Español