1. Introduction: The Invisible Backbone of Garment Manufacturing

In the complex workflow of garment manufacturing, fusible interlining is often referred to as the “invisible backbone” of a piece of clothing. Whether it is a high-end bespoke suit requiring the perfect drape or a fast-fashion brand prioritizing production efficiency, the choice of the right interlining directly impacts the garment’s lifespan, appearance, and market competitiveness.

For production managers and procurement decision-makers, choosing between Woven and Non-Woven interlining is not just a simple cost calculation; it is a technical strategic decision involving fabric mechanics, heat shrinkage rates, and the end-user experience. This article provides an in-depth exploration of the core differences between the two, helping your production line find the perfect balance between quality and profitability.

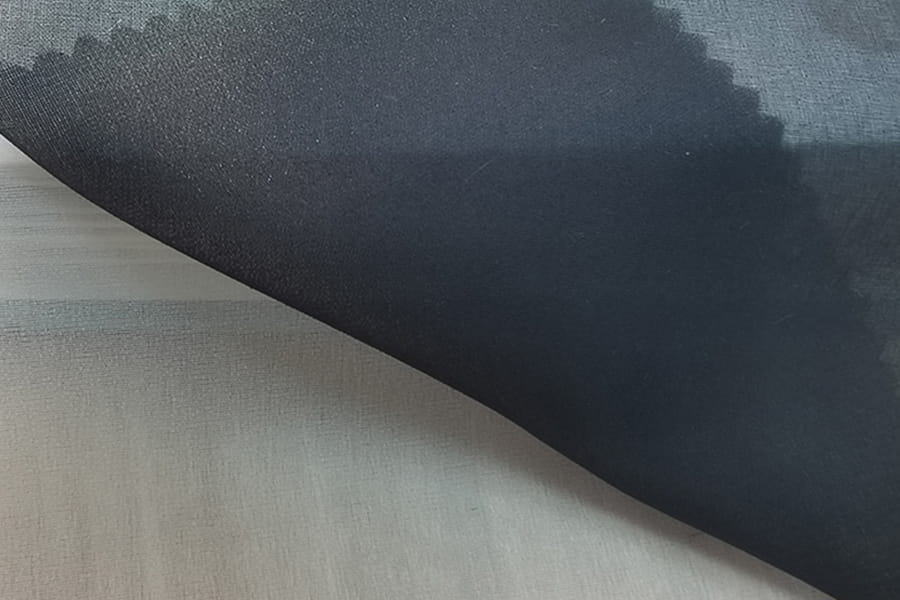

2. In-Depth Analysis: The Structural Excellence of Woven Fusible Interlining

Woven fusible interlining is created on a loom by interlacing warp and weft yarns. Because its manufacturing process is similar to that of the outer shell fabric, it achieves near-perfect physical harmony with high-value textiles.

2.1 Balance of Stability and Directional Forces

The primary SEO advantage of woven interlining lies in its structural integrity. Because it possesses a distinct grain line, it exhibits high predictability during the cutting and sewing processes. Using woven interlining in critical areas—such as full front fusing for suits, coat collars, and waistbands—effectively prevents fabric distortion or stretching caused by gravity or frequent movement. This “shape memory” is the secret to maintaining a crisp, tailored silhouette in premium apparel.

2.2 The Golden Partner for High-End Natural Fibers

For natural fibers such as wool, silk, or fine-combed cotton, woven fusible interlining is indispensable. It mimics the natural dynamics of the shell fabric, ensuring that the bonded composite fabric retains its original breathability and hand-feel. In the context of lean manufacturing, utilizing high-quality woven interlining significantly reduces return rates caused by bubbling or delamination, thereby protecting the brand’s market reputation.

2.3 Withstanding the Rigors of Industrial Laundering

Woven interlining excels in durability after repeated washing or dry cleaning. Its interlaced structure ensures that the adhesive (typically PA or PES hot-melt glue) penetrates and locks more uniformly within the fiber gaps. For corporate uniforms or premium shirts that require frequent laundering, the long-term bond strength provided by woven interlining is a core metric of quality control for any production line.

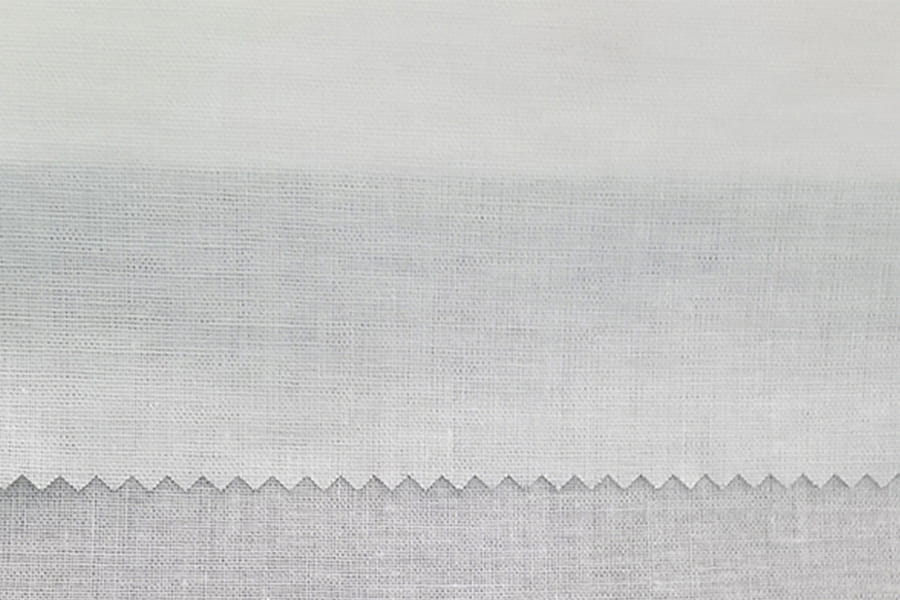

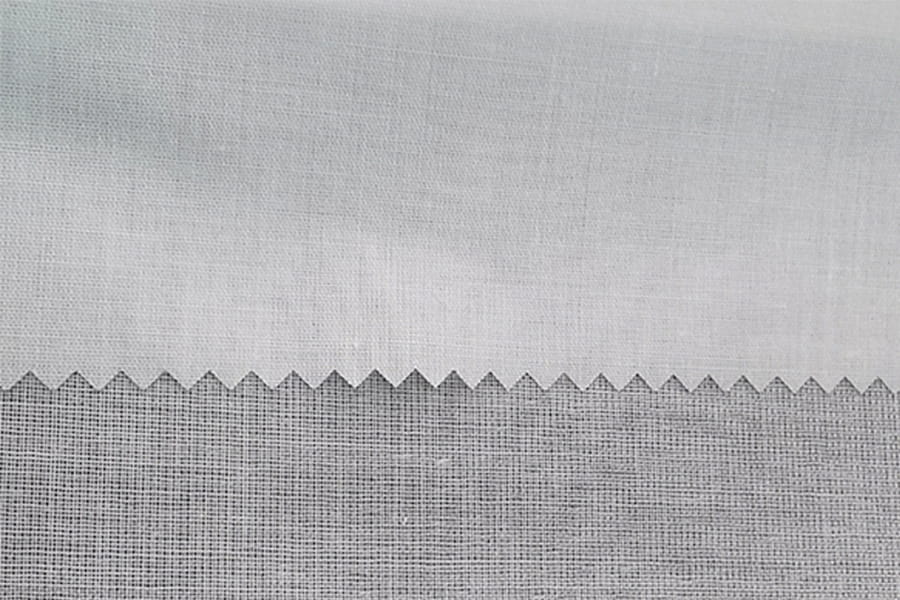

3. The King of Efficiency: The Logic of Using Non-Woven Fusible Interlining

Non-woven fusible interlining is produced by orienting or randomly arranging fibers and bonding them through chemical, thermal, or mechanical means. In production environments where output ratios and cost control are paramount, non-woven interlining holds the dominant market share.

3.1 Superior Cost-Effectiveness and Marker Utilization

From a supply chain management perspective, non-woven interlining is a powerful tool for reducing the “cost per garment.” Since it lacks a grain line (warp/weft direction), it allows for multi-directional marking and cutting. This non-directional characteristic maximizes raw material utilization and minimizes scrap waste. For factories producing tens of thousands of units annually, the savings generated here translate directly into increased profit margins.

3.2 Versatile Weights and Flexibility

The variety of non-woven interlining is immense—ranging from “featherweight” varieties that feel like tissue paper to heavy-duty, stiff versions. It is particularly suitable for reinforcing localized areas that do not require complex structural molding, such as pocket flaps, zipper edges, or shirt cuffs. In today’s market where lightweight fabrics are trending, low-GSM non-woven interlining provides invisible support without adding bulk to the garment.

3.3 A Catalyst for “Speed to Market”

In the fast-fashion industry, speed is a lifeline. Non-woven interlining is easy to cut and easy to bond, with relatively lower requirements for fusing machine precision. It shortens the production cycle, helping enterprises respond rapidly to market trends. While it may not match woven interlining in complex sculptural tailoring, its efficiency in standardized, high-volume apparel is unrivaled.

4. Woven vs. Non-Woven: Technical Specifications & Production Comparison

To assist your technical team in making a quick selection, we have summarized the core data in the comparison table below:

| Evaluation Metric | Woven Fusible Interlining | Non-Woven Fusible Interlining |

|---|---|---|

| Manufacturing | Interlaced Yarns (Woven on Looms) | Fiber Bonding (Chemical/Thermal) |

| Directional Constraint | Strong (Must align with grain) | Weak (Multi-directional cutting) |

| Hand-feel & Drape | Supple, moves with fabric | Stiffer, paper-like feel |

| Tensile Strength | Extremely High | Moderate to Low |

| Cost Investment | Higher (Premium choice) | Economic (Cost-effective) |

| Primary Application | Suits, coats, luxury corporate wear | Fast fashion, childrenswear, details |

| Laundering Life | Extremely long (Dry-clean safe) | Moderate (Fibers may degrade over time) |

5. Decision Making: Which One is Right for Your Production Line?

When choosing your interlining, your decision path should be based on these three core logics:

- Fabric Matching Principle: The rule is “like attracts like.” If the shell fabric is a woven natural fiber, prioritize woven interlining. If the shell is a knit or synthetic, non-woven or knitted interlining may offer better cost-performance.

- Stress Analysis: Consider which parts of the garment experience the most stress during wear. For collars, armholes, and waistbands that must maintain their shape long-term, consider using woven interlining locally even if the rest of the garment uses non-woven.

- Profit Targets: For high-end retail markets, using woven interlining adds perceived value and justifies a premium price. For mass-market products, optimizing the non-woven supply chain is the key to improving ROI.

6. Frequently Asked Questions (FAQ)

- What causes “strike-through” (glue seeping through) after fusing?

This is usually caused by excessive pressure, high temperatures, or a coating weight that is too heavy for the fabric thickness. Always perform a sample test before mass production. - Can woven and non-woven interlinings be used in the same garment?

Absolutely. Many sophisticated manufacturers use woven interlining for large panels to ensure silhouette stability while using non-woven for smaller, low-stress parts to save costs. - What is the shelf life of fusible interlining?

Because hot-melt adhesives degrade over time, it is recommended to store them in a cool, dry place. The effective shelf life is typically 12–24 months. - How do I test the quality of interlining?

Key testing metrics include peel strength, heat shrinkage consistency, and changes in hand-feel after washing.

7. References

- Wang, X. (2025). Advanced Textile Chemistry: The Science of Fusible Adhesives. Global Garment Research.

- Industrial Apparel Standards Board. (2024). Standard Operating Procedures for Interlining Selection in Mass Production.

- Lee, M. & Gupta, R. (2023). Sustainability Trends in Non-Woven Textile Manufacturing. Green Tech Apparel Journal.

English

English 中文简体

中文简体 русский

русский Español

Español